In the wake of the industrialization era, the aspects of production and manufacturing have found a boom all around the world. New industries, different modes of manufacturing, and capturing the machinery needs of the world was done at a fast pace. After decades of industrialization which is continuing all around the world one way or the other with automated as well as artificial intelligence-based equipment as well as processes that had taken a turn after the digitalization era. Today the manual labor on the workers’ staff and employees has been cut down by half all thanks to the automated system as well as the cut down of working hours based on the various norms and regulations by authorities.

Today the Manufacturing industries have evolved to one of the major sources of economy in different ways by providing the productional income, employment for many as well as the high amount of money involved. Today there are more medium as well as small-scale manufacturing units being set and they are striving towards excellence. With the newer innovations and technology being implemented to the industry the entire economy as well as performed related to be it’s in the excellence stage. However, with the impact of the pandemic disrupting the lives as well as the industries all around the world, there have been certain precautions concerning the growth.

Another aspect in regards to the manufacturing industry and its operations is that you will be needing the right tools which will back you up and support the operation for the day-to-day activities to the major ones. The challenges faced by manufacturing industries in their day-to-day operations are even more than the normal retail as well as a wholesale business because there is an additional element of functioning as well as the collection of raw materials to its manufacturing as well as the storage. In addition, the constraints, as well as the parameters involved in the manufacturing industry, is high in number, therefore, the need for dedicated management tools which will be supporting all-round the operations of the company is inevitable

This blog will focus on describing 5 Major Challenges Faced By The Manufacturing Industry. And How to Solve Them Effectively.

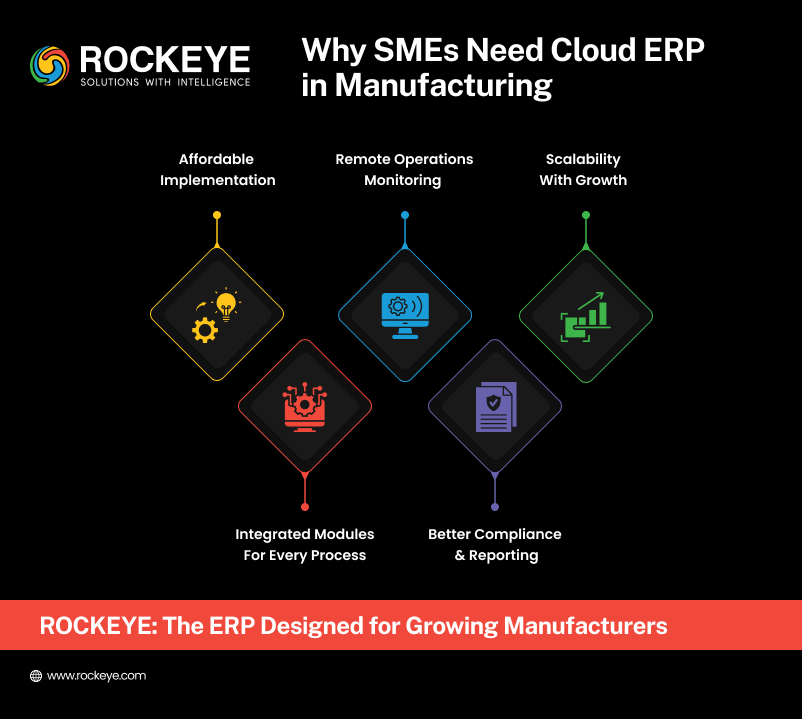

In regards to the operations of the manufacturing industries, the major challenge faced by them is the availability of dedicated management tools and systems which will support the management and the control of the operations. As all the operations are run by software solutions and automated tools, a dedicated cloud manufacturing software will be essential as it will allow the remote monitoring of the function even when the managers, as well as the business heads, are not at the manufacturing sites. The manufacturing ERP software which is available in the market will provide you with sufficient operational aspects along with the dedicated tools of operations. Moreover, it will be the apt solutions that will pave the way for the effective management of your manufacturing industry. Let’s initially understand the main 5 challenges faced by the manufacturing industry.

5 major Challenges in Manufacturing Industry

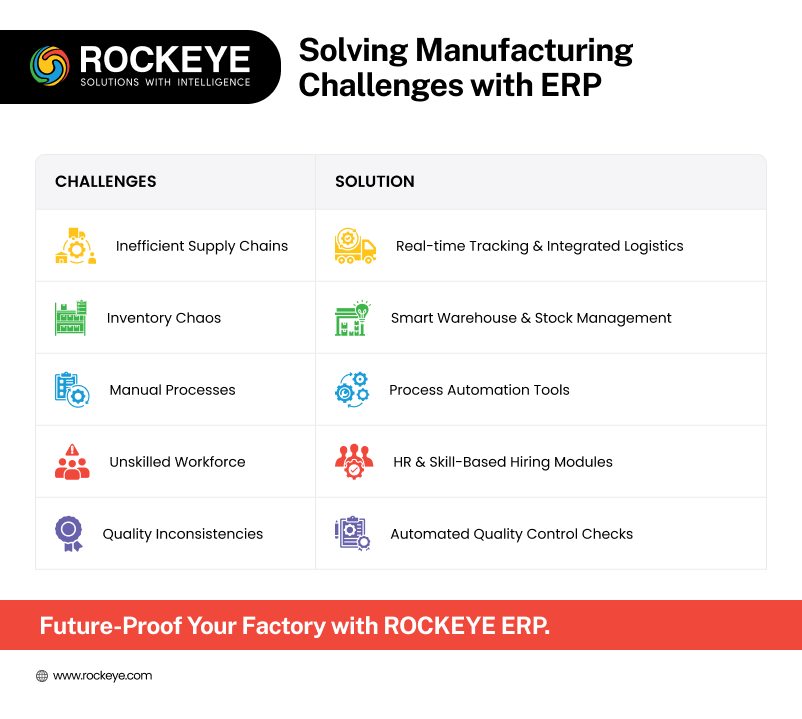

Ineffective supply chain operations:-

The supply chain of the products, as well as the raw material along with the right movement of its, is essential for the operations of the manufacturing industries. Moreover, an effective supply chain of operations will ensure that the demands of the customer are met efficiently taking the company operations to the next level and be run efficiently.

Lack of proper inventory management:-

The lack of effective inventory management results in effective supply chain operations which will disrupt the flow of the company operations. Without a dedicated inventory management system as well as tools you will not be able to store and distribute and use the products as well as the raw material required for the manufacturing operations to run effectively.

Bringing in automation:-

Automation is the key to the success of the operations of the manufacturing industries as it will reduce the load of the employee and will serve as a hassle-free tool of operations in regards to the routine functions that are one. With a dedicated management system that can control all the operations of your manufacturing facility, you will lack behind in the performance

Finding the right skilled persons:-

Employee hiring has become default these days and in regards to a manufacturing unit, the need to hire the rightful expertise as well as the right skills is much needed in the effectiveness of the operations. As there are numerous candidates available for a position today you will need to find an efficient management system that will support the operations of employee and skill hiring in regards to the manufacturing facilities.

Equity checking and keeping up with the standards:-

In order to maintain the efficiency and the expertise of the products, a rightful quality check in regards to the products manufactured should be done at different stages which will ensure that your products are at the right measurements, standards and quality. Without a dedicated system as well as the methodology of operations the operations of running quality checks will be tampered with and will be ineffective affecting the quality of your products and will have a direct effect on the business from the customer side.

As we have an understanding of the major challenges faced by manufacturing industries let’s now move on to understand how they will be effectively overcome.

How can we overcome the challenges in the Manufacturing Industry?

The implementation of the right ERP for manufacturing solutions for manufacturing industries will solve the challenges that are described above in the production facilities as well as business. ROCKEYE Manufacturing Suite, a prominent ROCKEYE ERP suite with dedicated cloud-based manufacturing software, offers an all-in-one platform tailored for operational excellence. Let’s understand how ROCKEYE Manufacturing Suite will help solve the challenges that are described above.

Effective supply chain management:

Cloud ERP software for manufacturers such as ROCKEYE will support the aspect of efficiency in the operations of product movement and distribution. With modules like Procurement and Inventory & Warehouse, businesses can track goods across multiple locations, manage suppliers, and ensure smoother logistics. Moreover, with the help of dedicated tools and functional options that are available, you will be able to run the operations of the supply chain with improved accuracy and effectiveness.

Dedicated Inventory management systems:

ERP suites for manufacturing such as ROCKEYE offer a dedicated Inventory & Warehouse module that allows you to manage product storage, batch management, warehouse operations, and streamline product movement. These functions support the entire supply chain operations of the manufacturing industry and can be customized to your unique workflow. All these aspects will be channelized in operations with a dedicated structure that is pre-defined by you based on the operations of your business.

Advancements through automation:

As mentioned earlier, automation is the key to the success of operations in a manufacturing industry without which you will not be able to move ahead in the functioning of a manufacturing business. With ROCKEYE Production, automation tools such as dynamic workflows, production templating, and real-time data capture support the functioning of production operations, reducing manual intervention and enhancing employee efficiency.

Dedicated HR management:

With the implementation of manufacturing ERP solutions, you will have a dedicated Human Resource module that will help you with employee management—from hiring through a structured recruitment process to payroll and training. With ROCKEYE’s HR module, businesses can manage performance, monitor attendance, and support the full employee lifecycle, helping to recruit and retain the right talent effectively.

Monitor and manage the quality of the products:

Quality management of the product is vital in the production-based industries. With integrated modules such as Production and Inventory, ROCKEYE enables businesses to set quality checkpoints and gain real-time visibility over production flows. This helps in monitoring product quality across various stages and ensures consistency in standards, ultimately enhancing customer satisfaction.

In conclusion:

A dedicated ERP for the manufacturing industry, such as the ROCKEYE Manufacturing Suite, will be the apt solution for overcoming the challenges in the manufacturing industry—helping managers and executives run operations with effectiveness and efficiency. With modules covering Production, Financial Accounting, Sales & Invoicing, Human Resource, Procurement, and Inventory & Warehouse, ROCKEYE empowers businesses with modern tools that are scalable, cloud-based, and tailored for real-time decision-making. The best ERP manufacturing software companies today focus on not just managing operations but transforming them—and ROCKEYE leads that transformation.

FAQs:

Q1. What are the biggest challenges faced by the manufacturing industry today?

The biggest challenges faced by the manufacturing industry today include ineffective supply chain operations, lack of proper inventory management, difficulty in bringing in automation, challenges in finding the right skilled persons, and issues related to equity checking and maintaining quality standards.

Q2. Why is the supply chain such a critical concern for manufacturers?

The supply chain of the products, as well as the raw material along with the right movement of it, is essential for the operations of the manufacturing industries. An effective supply chain ensures customer demands are met efficiently, helping operations run smoothly and at a higher level.

Q3. How does poor inventory management affect manufacturing operations?

Without a dedicated inventory management system and tools, storing, distributing, and using products and raw materials becomes ineffective, disrupting the flow of company operations and impacting overall productivity.

Q4. What role does automation play in the manufacturing sector?

Automation is the key to success in manufacturing operations as it reduces the workload of employees and ensures hassle-free execution of routine tasks. Without it, performance and efficiency are significantly impacted.

Q5. Why is hiring the right talent challenging in manufacturing?

Although numerous candidates may be available for positions, finding the rightful expertise and skills is essential for effective operations. The need for a proper management system to support employee and skill hiring is more critical in manufacturing facilities.