What is inventory shrinkage?

Inventory shrinkage, also called inventory loss, is when your physical inventory is less than the amount of inventory in your books. This loss can happen due to theft, damaged goods, or miscounting. Identifying the cause of inventory shrinkage is the first step to mitigating its effects and finding solutions to prevent shrinkage.

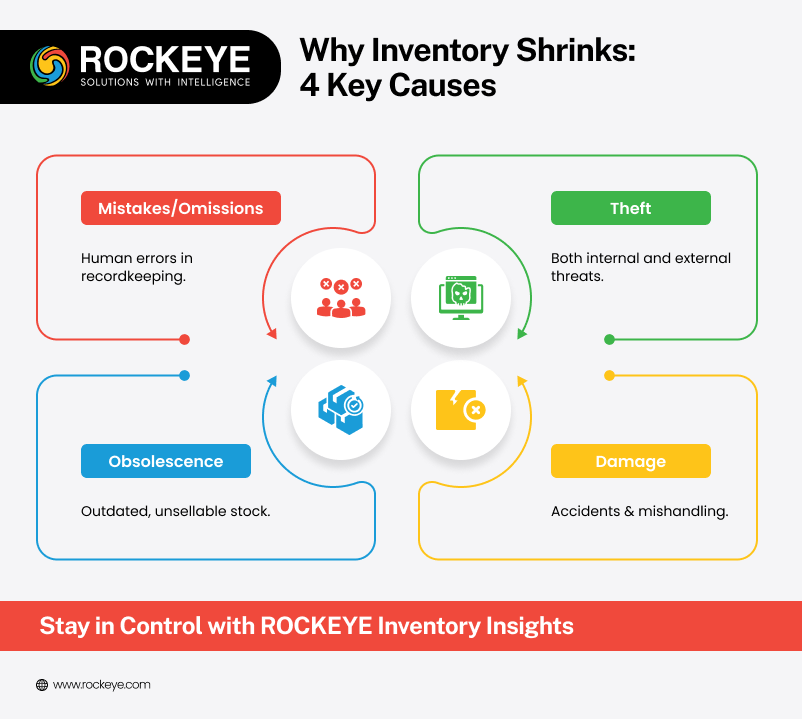

4 main causes of inventory shrinkage

Theft, damage, obsolescence, and mistakes/omissions are the four main malefactors of inventory shrinkage. Although there are technological steps that you can take to ensure you don’t lose any product (e.g., tagging merchandise with proprietary tracking tags), many prevention techniques rely on human vigilance.

1. Theft

Your customers may not treat your inventory as you would, meaning they may break or damage products in your store. Customers, unfortunately, also will steal from you. Consider instituting systems to prevent theft. One common example is asking clients to leave large bags and backpacks at the door.

Employee theft can also be a problem. Take measures to ensure that your employees know the consequences of theft and how it weaken everyone in the business.

2. Damage

Damage to the inventory is yet another reason that causes inventory shrinkage. This can happen as a result of accidents or poor handling. By regularly inspecting the inventory’s condition, you can prevent further shrinkage and improve your overall business performance.

3. Obsolescence

When a product becomes obsolete, it means that its customer base has moved on to something new. This means that the product no longer has a market and must be disposed of. In order to avoid inventory shrinkage, you should keep track of which products are becoming obsolete and dispose of them as soon as possible. To clear off the excess inventory, you can sell them at discounted prices or bundle them up.

4. Mistakes/Omissions

Inventory shrinkage is a common problem for businesses of all sizes. It can be caused by a number of factors, one of them being mistakes while recording the inventory. If you rely on manual inventory recording, it’s prone to errors, and you may end up noting the incorrect values.

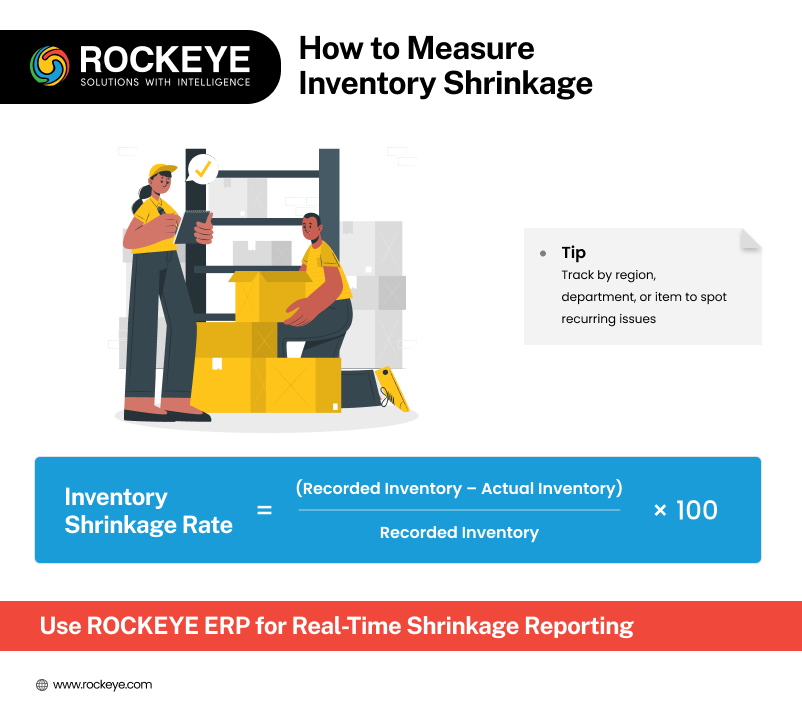

How to calculate inventory shrinkage rate?

Calculating the inventory shrinkage rate involves determining your total annual loss and dividing it by your total assets value. The result is the percentage of assets that are being lost each year.

Inventory shrinkage rates can be calculated for any part of a business: departments, regions, and divisions. This makes it possible to identify trends or areas where most of your losses are occurring, so you can find solutions to minimize losses.

Inventory Shrinkage Rate = (Recorded Inventory – Actual Inventory) / Recorded Inventory

Multiply the answer by 100 to calculate the percentage.

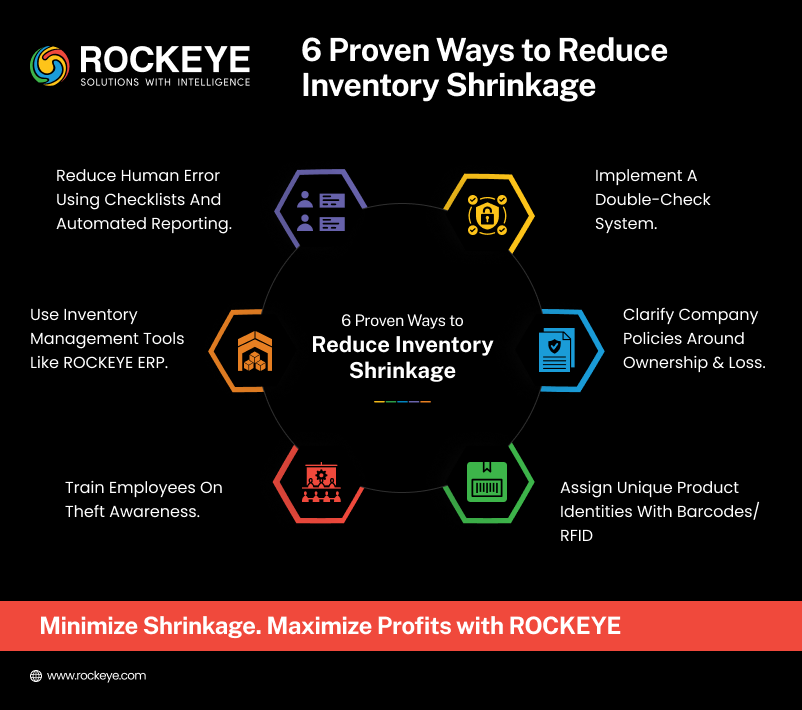

6 Strategies to reduce inventory shrinkage

1. Implement a double-check system

Implementing a double-check system can help reduce inventory shrinkage. The double-check system is a process where the company checks stock levels twice a day to make sure that there is no accumulation of unsold items. This way, the company can avoid any potential shortages or price increases. In addition, using ERP solutions such as ROCKEYE Inventory And Warehouse Solution can help to reduce inventory shrinkage.

ROCKEYE helps companies to track inventory levels and make sure that products are in stock when they are needed. This way, the company can avoid any shortages and price increases.

2. Clarify company policies

Set clear policies regarding theft, employee property, and company property. This removes any ambiguity regarding what belongs to whom and how theft is handled. Being clear helps avoid confusion and miscommunication.

3. Give products unique identities

Reducing inventory shrinkage is essential to keeping your business running smoothly. One strategy that you can use to reduce inventory is to give products unique identities. This will make it easier for customers to navigate your product offerings and make it more difficult for competitors to steal your customers.

Additionally, ROCKEYE plays an important role in reducing inventory shrinkage. By automating processes and providing detailed information about inventory levels, you can ensure that your products are available when and where they are needed most.

4. Train employees about theft prevention

Theft prevention begins with employee training. Train new employees to identify warning signs of theft and report theft when they see it. Teach employees that theft, whether internal or external, has a negative impact on your bottom line and customer satisfaction. Use clear language in your policies and procedures manual to outline the repercussions of theft-related activities.

5. Utilize inventory management software

Reducing inventory shrinkage is one of the most important strategies to achieve success in your business. Investing in inventory management with software like ROCKEYE Systems can help you achieve this goal.

With ROCKEYE , you can keep tabs on your orders from multiple channels and gain real-time visibility over your inventory. This way, you can keep up with inventory movements and track it from receiving to dispatching. Using the stocktake feature, you can easily reconcile the physical inventory with the one in your records. This way, you can easily identify any discrepancies.

6. Reduce human error with checklists and reporting

Reducing inventory shrinkage is an important goal for any business. Unfortunately, human error is a major cause of inventory mistakes. In order to reduce the chances of making a mistake, it’s important to use checklists and reporting strategies.

With ROCKEYE , you can record all your incoming inventory with barcode scanners. Whenever you scan the code, the inventory gets accurately registered in the system, leaving no scope for incorrect data entry leading to inventory shrinkage. Moreover, barcode scanning is comparatively faster.

FAQs

1. What is inventory shrinkage?

Inventory shrinkage, also called inventory loss, is when your physical inventory is less than the amount of inventory in your books. This loss can happen due to theft, damaged goods, or miscounting.

2. What are the main causes of inventory shrinkage?

Theft, damage, obsolescence, and mistakes/omissions are the four main malefactors of inventory shrinkage.

3. How can theft lead to inventory shrinkage?

Customers may break, damage, or steal products. Employee theft can also be a problem. It’s important to have systems and clear consequences in place to prevent theft.

4. What role does damage play in inventory shrinkage?

Damage can result from accidents or poor handling. By regularly inspecting the inventory’s condition, you can prevent further shrinkage and improve business performance.

5. How does product obsolescence cause inventory shrinkage?

When a product no longer has a market and must be disposed of, it leads to shrinkage. You should keep track of obsolete products and dispose of them quickly, possibly by offering discounts or bundles.