Introduction: Vietnam’s Agro-Processing Industry at a Turning Point

Vietnam’s agro-processing sector is booming, from coffee plantations in the Central Highlands to seafood hubs in the Mekong Delta. For CEOs, CFOs, and CTOs, this growth comes with high stakes: fragmented supply chains, raw material volatility, multi-plant alignment challenges, and strict quality requirements.

For production managers, inventory managers, procurement leads, quality managers, and maintenance managers, supply chain management for manufacturing is no longer just about operational efficiency; it’s a strategic lever for profit. Industrial digital control systems and commercial control systems are helping agro-processing plants optimize throughput, control margins, and reduce leaks across the manufacturing chain.

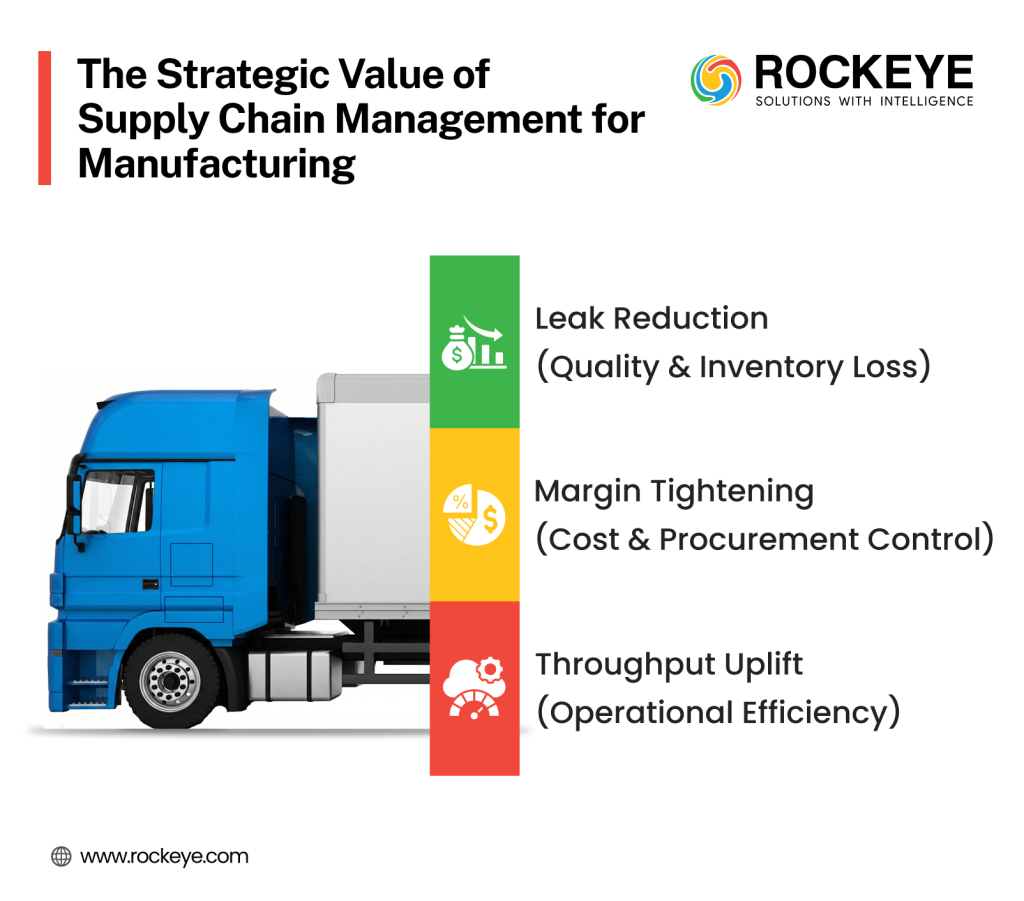

With integrated supply chain processes, companies can achieve measurable ROI in just 90 days:

- Leak Reduction: raw material loss, production variance

- Margin Tightening: BOM vs actual variance, procurement leakages

- Throughput Uplift: reduced downtime → higher OEE

Vietnam-specific Manufacturing Constraints Affecting Profitability

Vietnam’s agro-processing industry faces unique operational challenges that directly affect profitability:

Multi-plant Coordination: Many manufacturers operate across several sites. Ensuring consistent production planning and performance metrics is critical.

Raw Material Volatility: Seasonal fluctuations, weather risks, and quality variation in crops like coffee, rice, and seafood ingredients challenge procurement and production planning.

Quality Traceability: Global export standards require full traceability, from farm to finished product. Any lapse leads to rejected shipments and lost revenue.

Production Planning & OEE: Plant managers must balance production capacity with demand variability while minimizing downtime and waste.

An Interesting Read: Integrated Supply Chain Visibility for Manufacturing Plants – Inbound + Outbound Control

Why Supply Chain Management for Manufacturing Matters

For agro-processing leaders in Vietnam, effective supply chain integration drives measurable outcomes:

1. Leak Reduction (Quality & Inventory Loss)

- Production vs Plan variance reduction

- Raw material spoilage control

- Inventory mismatch prevention

CFO Insight:

Even a 1% reduction in raw material leak translates into a 2–4% margin uplift in high-volume categories like coffee and seafood.

2. Margin Tightening (Cost & Procurement Control)

- BOM vs actual variance monitoring

- Supplier scoring and procurement compliance

- Raw material cost variance control

CFO ROI Lens:

Plants often recover USD 250k–1.1M per plant by tightening procurement and production variances within 90 days.

3. Throughput Uplift (Operational Efficiency)

- Line productivity improvement

- Preventive maintenance to reduce downtime

- Real-time Operational Throughput Control

For example, a Production Manager using a Commercial Control System can monitor OEE in real time, identify bottlenecks, and adjust production schedules to maximize throughput without increasing costs.

Integrating Technology for Profit

Instead of generic ERP claims, Vietnam’s agro-processing plants require Industrial Digital Control Systems that unify production, procurement, inventory, quality, and maintenance.

Key Features Include:

- Production Module: Align production planning with real-time raw material availability, OEE monitoring, and preventive maintenance schedules.

- Inventory & Warehouse Module: Track material usage accuracy, reduce spoilage, and optimize stock across multiple plants.

- Procurement & Sourcing Module: Monitor supplier performance, manage procurement compliance, and control raw material volatility.

- Transport Management Module: Ensure timely delivery of inputs and outputs, reducing spoilage and logistics delays.

- Quality Module: Enable traceability, compliance with export standards, and product consistency.

- Asset/Maintenance Management Module: Implement preventive maintenance to reduce unplanned downtime and ensure continuous throughput.

By combining these modules into an integrated supply chain solution, agro-processing plants achieve end-to-end visibility, predictive insights, and measurable ROI in 90 days.

Also Read: 6 Top Challenges of Supply Chain Collaboration and Ways to Overcome Them

Industrial Messaging Pillars

ROCKEYE’s solution aligns with three core industrial messaging pillars:

- Financial Governance: Monitor procurement compliance, track BOM vs actual variance, and control COGS.

- Operational Throughput Control: Real-time visibility of production lines ensures uptime, productivity, and plant-level efficiency.

- Predictive Intelligence: Predictive analytics for preventive maintenance, demand planning, and quality control reduces waste and mitigates operational risk.

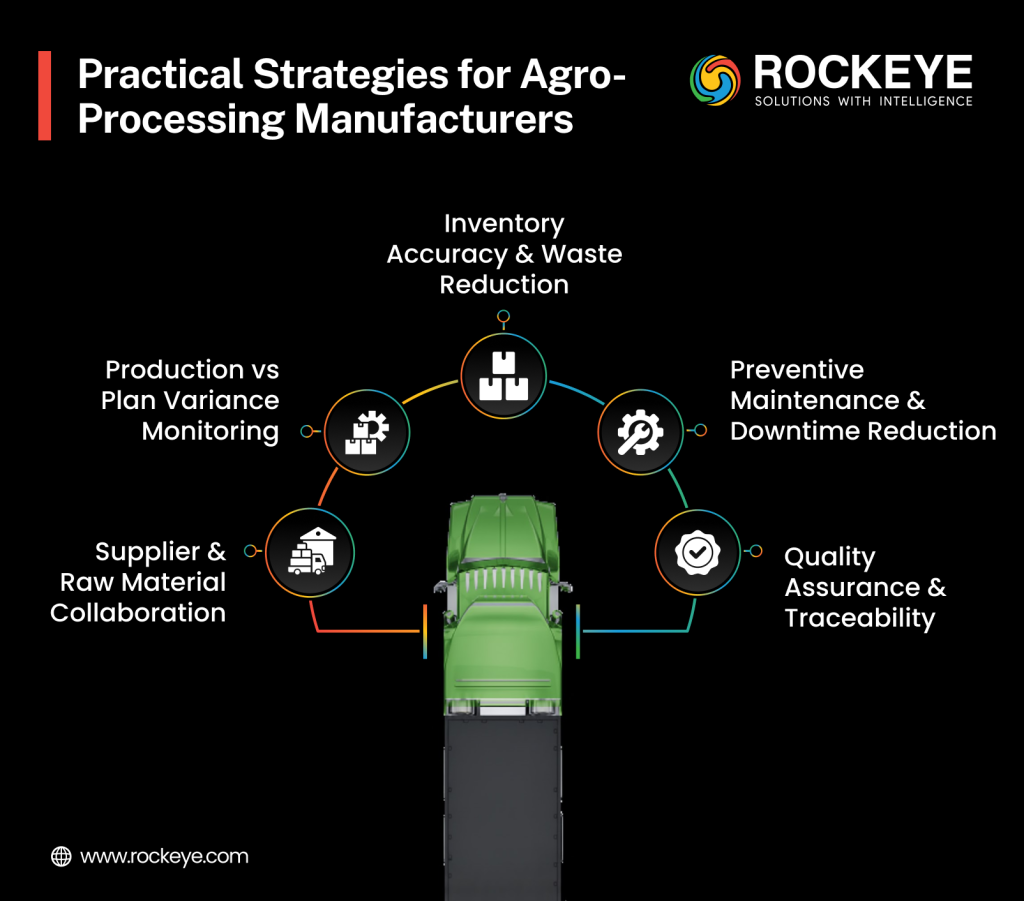

Practical Strategies for Agro-processing Manufacturers

Practical strategies that help Vietnam’s agro-processing plants cut leaks, tighten margins, and boost throughput. Designed for production, procurement, and quality leaders who want measurable performance gains across the manufacturing chain.

1. Supplier & Raw Material Collaboration

For Procurement Leads: Score suppliers, enforce procurement compliance, and forecast material volatility to prevent shortages.

2. Production vs Plan Variance Monitoring

For Production Managers: Compare scheduled vs actual production, identify bottlenecks, and take corrective actions in real time.

3. Inventory Accuracy & Waste Reduction

For Inventory Managers: Track material usage accurately, reduce spoilage, and optimize multi-plant stock allocation.

4. Preventive Maintenance & Downtime Reduction

For Maintenance Managers: Use predictive intelligence to schedule maintenance proactively, ensuring minimal production interruptions.

5. Quality Assurance & Traceability

For Quality Managers: Monitor raw material quality, process parameters, and product compliance for export standards.

Vietnam-Specific ROI Levers

By leveraging ROCKEYE’s Industrial & Manufacturing Digital Control System in Vietnam, plants can see tangible outcomes:

- Leak Reduction: Identify raw material loss and production variance quickly.

- Margin Tightening: Monitor BOM vs actual variance and procurement leakages to control costs.

- Throughput Uplift: Reduce downtime and improve OEE, ensuring higher output without increasing labor or energy costs.

These improvements are measurable within the first 90 days of implementation, giving leaders confidence in ROI.

You Might Enjoy Reading: 5 Practical Steps to Strengthen Your Supply Chain Performance

Competitive Advantage Through Integrated Supply Chain Planning

Integrated supply chain planning gives manufacturers tighter control over materials, production, and costs, directly influencing margin performance.

1. Multi-plant Alignment

Integrated systems provide cross-plant visibility and planning to ensure consistent production and quality.

2. Raw Material Volatility Management

Real-time procurement and inventory monitoring allow Procurement Leads to react swiftly to supply fluctuations.

3. Traceable Quality Assurance

Quality Managers can maintain end-to-end traceability, ensuring compliance with local and global standards.

4. Operational Efficiency

Production Managers and Maintenance Teams achieve higher throughput and lower unplanned downtime, boosting overall plant OEE.

5. Data-driven Decision Making

Finance Controllers, CEOs, and CTOs get actionable insights to optimize COGS, reduce leakages, and make strategic growth decisions.

ROCKEYE for Agro-Processing Vietnam

ROCKEYE provides production planning, raw-material traceability, quality control, preventive maintenance, and procurement governance, all in a single Industrial Digital Control System.

Plants can achieve integrated supply chain planning, ensuring leak reduction, margin tightening, and throughput uplift with modules covering:

- Production Management

- Inventory & Warehouse

- Procurement

- Transport Management

- Asset Management

- Maintenance & Services

FAQs

1. What is supply chain management for manufacturing in agro-processing?

Supply chain management in agro-processing manufacturing involves coordinating sourcing, production, quality control, inventory, and distribution to optimize cost, efficiency, and product quality. It ensures that raw materials and finished goods flow smoothly while maintaining compliance and operational standards across all facilities.

2. How does supply chain integration improve manufacturing efficiency?

Supply chain integration enables real-time coordination across production, procurement, inventory, and quality functions. By reducing delays, waste, and unplanned downtime, it ensures smoother operations, higher throughput, and improved responsiveness in agro-processing plants.

3. What are the best integrated supply chain solutions for agro-processing?

Top solutions include Industrial digital control systems (IDCS), commercial control systems (CCS), and integrated manufacturing control platforms (IMCP). These platforms provide end-to-end operational visibility, predictive analytics, real-time monitoring, and throughput control, helping manufacturers optimize efficiency and profitability.

4. How does the supply chain for manufacturing impact production performance?

An effective supply chain ensures that raw materials are available on time, quality standards are maintained, and production schedules are optimized. This reduces downtime, prevents bottlenecks, and maximizes throughput, directly improving plant performance.

5. What factors shape an effective manufacturing chain in global markets?

Key factors include traceability, predictive planning, supplier compliance, cost control, operational throughput, and sustainability metrics. Companies that focus on these areas can maintain consistent quality, improve efficiency, and meet global market standards.

6. How can supply chain management for manufacturing reduce operational costs?

Supply chain management reduces costs through better procurement governance, accurate inventory management, variance control between production and plan, and preventive maintenance. By minimizing wastage and improving operational visibility, plants can protect margins and enhance ROI.

7. What role does supply chain integration play in agro-processing growth?

Integration improves profitability, product quality, operational throughput, and export readiness. It also mitigates risks from raw material volatility, production disruptions, and fragmented supplier networks, enabling sustainable growth for agro-processing manufacturer

8. How do integrated supply chain solutions enhance product quality?

Integrated solutions monitor every step of production, enforce quality standards, and provide real-time alerts for deviations. This ensures consistent outputs, reduces defects, and builds trust with clients and export partners.

9. What challenges affect the manufacturing chain in agro-processing industries?

Common challenges include raw material volatility, multi-plant coordination, inconsistent quality, unplanned downtime, and fragmented supplier networks. Overcoming these requires robust digital control, predictive planning, and integrated operational systems.

10. How can companies build a strong supply chain for manufacturing globally?

To build a strong global supply chain, companies should implement industrial digital control systems, enforce commercial controls, optimize procurement, maintain preventive maintenance schedules, and align production across multiple plants. This ensures operational consistency, cost efficiency, and global competitiveness.