Indonesia is emerging as a manufacturing powerhouse in Southeast Asia. From cement and steel to agro-processing and cold-chain logistics, the nation’s industrial base is expanding rapidly. Global demand is surging, supply chains are growing complex, and digital transformation is on every manufacturer’s agenda.

Yet, amid this growth, many Indonesian manufacturers are hitting the same barrier: margin erosion despite ERP adoption. Traditional manufacturing ERP systems in Indonesia were designed to track inventory, production, and finances, but they often fall short in real-time cost control, asset efficiency, and operational visibility.

This is where Industrial Commercial Control Systems (ICCS) step in. ICCS isn’t just another ERP, it’s a profit-layer platform that addresses the operational leaks ERP misses. Let’s explore why Indonesian manufacturers need ICCS now more than ever.

Indonesia’s Manufacturing Is Growing, But Margin Discipline Is Not

Manufacturing is a cornerstone of Indonesia’s economic growth, contributing significantly to GDP and employment. Industries such as cement, steel, mining, and FMCG processing are scaling operations rapidly. Large construction and EPC fleets are expanding, and cold-chain logistics are becoming more critical as consumption patterns shift.

However, with growth comes complexity. Many plants face challenges like:

- Rising raw material costs and fluctuating commodity prices

- Operational inefficiencies in production, maintenance, and supply chains

- Hidden inventory losses across warehouses and depots

- Project overruns in large construction and EPC operations

While ERP solutions are present, they were often designed for transaction recording and reporting, not for real-time operational insights or profit protection. This leaves manufacturers in Indonesia with a gap between growth and margin control.

Do You Know?The manufacturing ERP systems in Indonesia are already valued at USD 119.34 million in 2025 and are set to reach USD 180.19 million by 2030 at an 8.59% CAGR, driven by metals, mining, construction, and food processing.

The Ground Reality: Cost Leaks Indonesia’s ERP Systems Cannot Catch

Even with a modern cloud ERP for manufacturing in Indonesia, plants often struggle to:

1. Pinpoint cost leakages at the production level

Inefficient batch processing, machine downtime, and scrap loss often go unnoticed.

2. Track inventory discrepancies in real time

Material theft, wastage, or misplacement leads to invisible cost erosion.

3. Manage multi-site operational visibility

ERP systems may consolidate financial data but fail to provide plant-to-plant operational clarity.

4. Ensure project-level profitability in complex EPC operations

Cost overruns and delayed procurement decisions hurt margins before leadership even notices.

In short, traditional ERP captures financial and transactional data, but it rarely connects production realities to profitability. For Indonesian manufacturers, where margin pressure is intensifying, this is a critical blind spot.

Why ICCS Is the Profit Layer Indonesian Manufacturers Are Missing

Industrial Commercial Control Systems complement ERP systems by providing deep operational and commercial control. While ERP tracks “what happened,” ICCS answers why costs are leaking and how to fix them.

Key differentiators of ICCS for Indonesian manufacturers:

1. Real-Time Cost Visibility

Track actual production costs against budgets and forecasts. Identify cost overruns before they escalate.

2. Operational Insights Across Assets

Monitor equipment efficiency, maintenance schedules, and asset utilization for better ROI.

3. Integrated Procurement & Project Management

Streamline vendor management, procurement cycles, and project budgets to prevent delays and extra expenses.

4. Profit Protection Layer

ICCS acts as a commercial control system, proactively reducing financial leakages, unlike standard ERP, which reacts to discrepancies after the fact.

By adding ICCS on top of existing ERP infrastructure, Indonesian manufacturers gain a strategic profit advantage.

Also Read: How Fuel Depots in Indonesia Lose Margin Without Real-Time Commercial Control

Module-Level Mapping: How ICCS Can Fix Indonesia’s Real Bottlenecks

Let’s break down ICCS modules and see how they solve critical challenges in Indonesian plants:

1. Cost Control Modules

- Track actual vs planned costs in real time.

- Identify hidden inefficiencies in production, labor, and materials.

- Optimize energy, maintenance, and operational expenses.

2. Inventory & Warehouse Management

- Eliminate stock discrepancies across depots and warehouses.

- Automate reorder points, batching, and material movement.

- Improve raw material and finished goods tracking.

3. Production Suite

- Capture real-time production data.

- Monitor machine utilization, downtime, and scrap rates.

- Ensure production planning aligns with demand.

4. Procurement & Financial Accounting

- Streamline purchase approvals, vendor compliance, and budget adherence.

- Integrate with financials to improve cash flow visibility.

- Reduce manual errors in invoicing and vendor payments.

5. Asset Management & Maintenance

- Predictive maintenance schedules reduce unplanned downtime.

- Track asset lifecycle and maximize equipment ROI.

- Plan capital expenditures based on operational insights.

6. Project Management

- Monitor project budgets, timelines, and resources.

- Ensure EPC projects and construction operations remain profitable.

- Reduce cost overruns with real-time alerts.

7. HR/Payroll

- Align workforce deployment with production needs.

- Track labor costs against project budgets.

- Ensure compliance with Indonesian labor laws.

ICCS modules integrate operational and financial data into a single, actionable platform, giving executives the tools to drive profitability proactively.

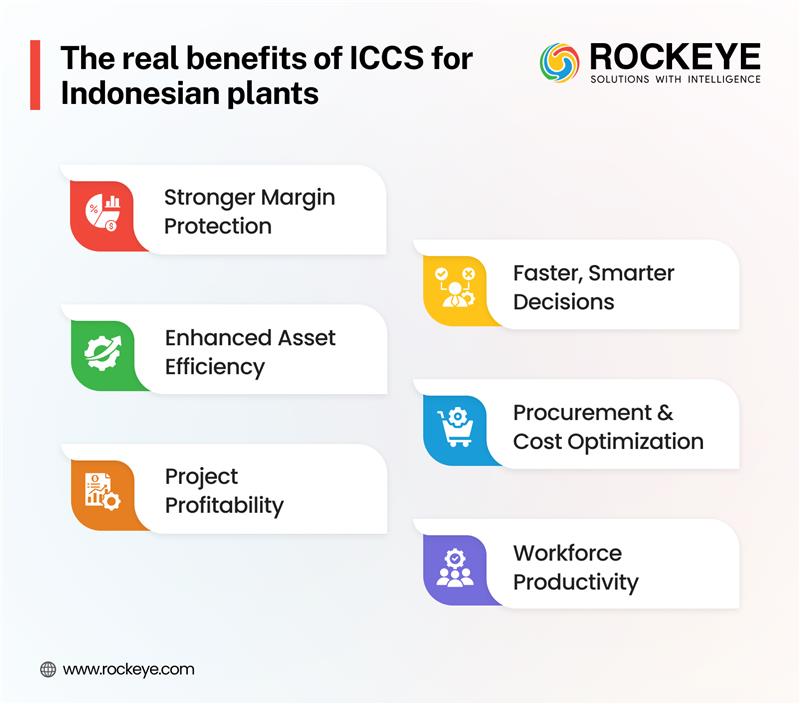

What Indonesian Plants Actually Gain From ICCS

When Indonesian manufacturers implement ICCS, the gains are tangible:

1. Stronger Margin Protection

Reduce hidden losses in production, inventory, and projects.

2. Faster, Smarter Decisions

Real-time operational dashboards empower plant managers and CFOs.

3. Enhanced Asset Efficiency

Maximize equipment uptime and lifecycle value.

4. Procurement and Cost Optimization

Track every purchase and contract against operational requirements.

5. Project Profitability

EPC and large-scale projects can now deliver on time and within budget.

6. Workforce Productivity

Optimize labor allocation with HR insights linked to production outputs.

Must Read: Integrated Supply Chain Visibility for Manufacturing Plants – Inbound + Outbound Control

The Strategic POV for CFOs, COOs, Plant Directors & Procurement Heads

For CFOs:

- ICCS provides a real-time manufacturing cost control system, ensuring that financial performance aligns with operational reality.

- Enables strategic allocation of working capital, avoiding wastage in raw materials and production inefficiencies.

For COOs & Plant Directors:

- Offers a manufacturing visibility platform across multiple plants and sites.

- Improves production planning, maintenance, and resource utilization, reducing operational bottlenecks.

For Procurement Heads:

- Streamlines vendor management and purchase approvals.

- Reduces cost leakage in procurement and ensures alignment with project timelines.

With ICCS, leadership can move from reactive problem-solving to proactive margin control, a competitive edge in Indonesia’s growing manufacturing landscape.

Why ROCKEYE

Among ICCS providers, ROCKEYE stands out for Indonesian manufacturers, because it is a complete Industrial Commercial Control System tailored to complex industries. ROCKEYE’s Manufacturing Suite has the following:

- Localized for Southeast Asia: ROCKEYE is designed to handle the tax structures, compliance standards, and operational realities of Indonesian plants.

- Integrated Modules: From cost control to HR/payroll module, it provides a full-suite solution under one platform.

- Real-Time Insights: Helps executives see margins, bottlenecks, and opportunities instantly.

- Scalable Across Industries: Works for cement, steel, mining, agro-processing, cold-chain logistics, and EPC fleets.

ROCKEYE transforms traditional ERP investments into profit-protecting platforms, ensuring that growth in Indonesia translates to real, measurable profitability.

Explore ROCKEYE’s Supply Chain Suite to see how ICCS can revolutionize your plant operations.

Conclusion

Indonesia’s manufacturing sector is at a turning point. While ERP systems have been invaluable for financial and transactional control, they no longer suffice for margin protection, operational visibility, and profit intelligence.

Industrial Commercial Control Systems, like ROCKEYE, provide the missing layer that ensures cost discipline, operational efficiency, and project profitability.

For CFOs, COOs, plant directors, and procurement heads, ICCS is not just a software upgrade; it’s a strategic lever for sustainable growth and competitive advantage.

By embracing ICCS, Indonesian manufacturers can finally bridge the gap between operational execution and financial performance, turning growth into real profitability.

FAQs

1. How is ICCS different from traditional manufacturing ERP systems in Indonesia?

ICCS goes beyond what traditional manufacturing ERP systems offer by adding a profit-protection and real-time operational visibility layer. While ERPs focus on recording transactions, ICCS actively tracks live production performance, asset utilization, hidden cost leaks, and operational deviations. This makes ICCS ideal for Indonesian manufacturers who need deeper control over costs, efficiency, and on-ground operations.

2. Can ICCS work with existing ERP solutions?

Yes. ICCS is designed to integrate seamlessly with local Indonesian ERP systems. Instead of replacing ERP, it enhances it with real-time operational insights, allowing manufacturers to gain live visibility into production, procurement, warehousing, fuel, assets, and overall cost control.

3. Which industries in Indonesia benefit most from ICCS?

ICCS delivers maximum value for industries with complex operations or high cost sensitivity, such as cement, steel, mining, foundries, EPC contractors, construction fleets, cold-chain logistics, FMCG, and agro-processing. These sectors rely heavily on real-time cost control, equipment efficiency, and production optimization, areas where ICCS provides a measurable impact.

4. What are the key modules of ICCS?

ICCS includes a wide suite of modules such as cost control, inventory & warehouse management, production monitoring suite, procurement & financial accounting, as well as asset management, preventive maintenance, HR/payroll, and project management. Together, they create a unified ecosystem for end-to-end industrial operations.

5. How does ICCS improve plant profitability?

ICCS helps manufacturers boost profitability by detecting operational leakages, optimizing production cycles, reducing wastage, improving procurement accuracy, and providing real-time dashboards for decision-making. This leads to better margins, higher throughput, and faster ROI for Indonesian plants.

6. Why choose ROCKEYE ICCS?

ROCKEYE ICCS is a localized, full-suite Industrial Commercial Control System built specifically for Southeast Asian manufacturing and contracting industries. It offers end-to-end control across cost, procurement, production, warehousing, assets, and compliance, giving manufacturers a single platform to run operations efficiently and profitably.