Table of Contents

Numbers are in front of us. Downstream logistics isn’t just complex; it’s massive. Nearly 65% of the world’s oil volume moves through transport networks that demand precision, visibility, and speed.

Now imagine unlocking over $1 in cost savings per barrel, simply by digitizing how those fleets, terminals, and routes operate. Sounds bold?

One Asian national oil company did exactly that, generating $200–$300 million in value in just 18 months through analytics-driven logistics.

This is where the Transport Management System (TMS) reshapes the downstream game. Built right into your existing Oil & Gas systems, it operates seamlessly, giving you real-time insights, optimized routes, and enhanced efficiency. TMS offers seamless, real-time insights that keep your operations efficient, agile, and ready for anything.

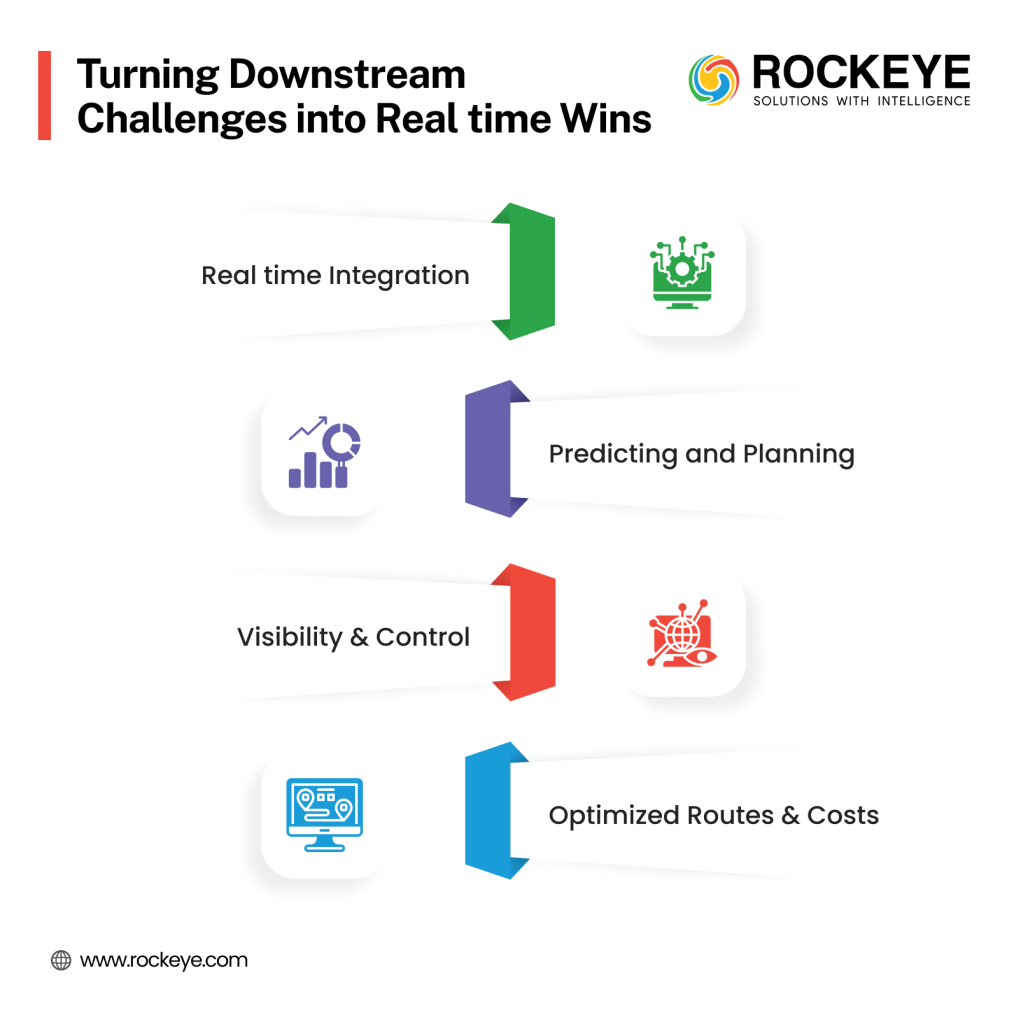

Tackling Downstream Volatility with Smarter, Real-time Decisions

Downstream operations move fast and often unpredictably. Refinery outputs fluctuate, and retail demand spikes. Traffic bottlenecks appear out of nowhere.

Here’s where a transport management system makes the difference, turning volatility into opportunity instead of setbacks.

Real-time Data that Lets You React Instantly

Built into your existing systems, the TMS pulls real-time data from GPS, IoT sensors, and connected logistics networks. Dispatch teams can dynamically adjust routes, schedules, and resource allocation the moment conditions change.

Stay Ahead with Predictive Planning

The smartest TMS doesn’t just react; it predicts. Risk-adjusted planning allows operators to model “what-if” scenarios, from supplier changes and route diversions to equipment downtime, so surprises don’t derail operations.

See Everything, Control Everything

Visibility is the key to control. The system provides live shipment tracking and automated alerts for delays, route deviations, or compliance issues, keeping operations transparent and manageable.

Optimized Routes, Leaner Costs

Efficiency goes beyond speed. By minimizing idle time, fuel burn, and redundant mileage, the TMS reduces operational costs while shrinking your carbon footprint.

How an AI-powered Transport Management System Functions within an Oil & Gas System?

In today’s downstream world, operations move fast, and surprises are the norm. Refinery outputs change, retail demand spikes, and traffic or weather can throw schedules off at any moment.

An AI-powered Transport Management System (TMS) built into your Oil & Gas system turns this chaos into clarity.

Real-time Decisions, Every Time

The TMS constantly pulls data from GPS, IoT sensors, and connected logistics systems. It doesn’t wait for problems to happen; it helps dispatch teams adjust routes, schedules, and resources instantly. The result? Decisions that are smarter, faster, and fully automated.

Seamless Connectivity Across Terminals

Whether it’s a refinery floor, a storage depot, or a remote terminal, all parts of your network communicate seamlessly.

Lightweight protocols like MQTT send real-time updates from remote sensors, while OPC-UA ensures secure communication between automation systems and enterprise IT. Everything talks to everything else, automatically.

Optimized Operations, Leaner Costs

AI-powered algorithms constantly analyze routes, schedules, and resource allocation. It reduces fuel use, cuts idle time, and lowers operational costs, all while improving delivery reliability. And because it’s built into your existing system, there’s no extra software or installation, just efficiency from day one.

Always Learning, Always Improving

One of the biggest perks of an AI-powered TMS is continuous learning. The system analyzes historical data, spots patterns, and improves predictions over time. Every route, every delivery, and every decision becomes smarter.

Also read: 7 Essential Features of Modern Terminal Management Systems

How AI and ML Capabilities Can Make Transport Management Software More Efficient

AI and ML are changing how downstream transport works. It guides Oil and Gas enterprises to shift from reacting to predicting. Built into modern TMS, they analyze live data from terminals, sensors, and vehicles to forecast what’s coming next.

The system can predict tank depletion, spot route inefficiencies, and even anticipate maintenance needs before breakdowns occur. Machine learning studies past transport patterns to recommend the best dispatch schedules or rerouting options in real time, keeping operations smooth and cost-efficient.

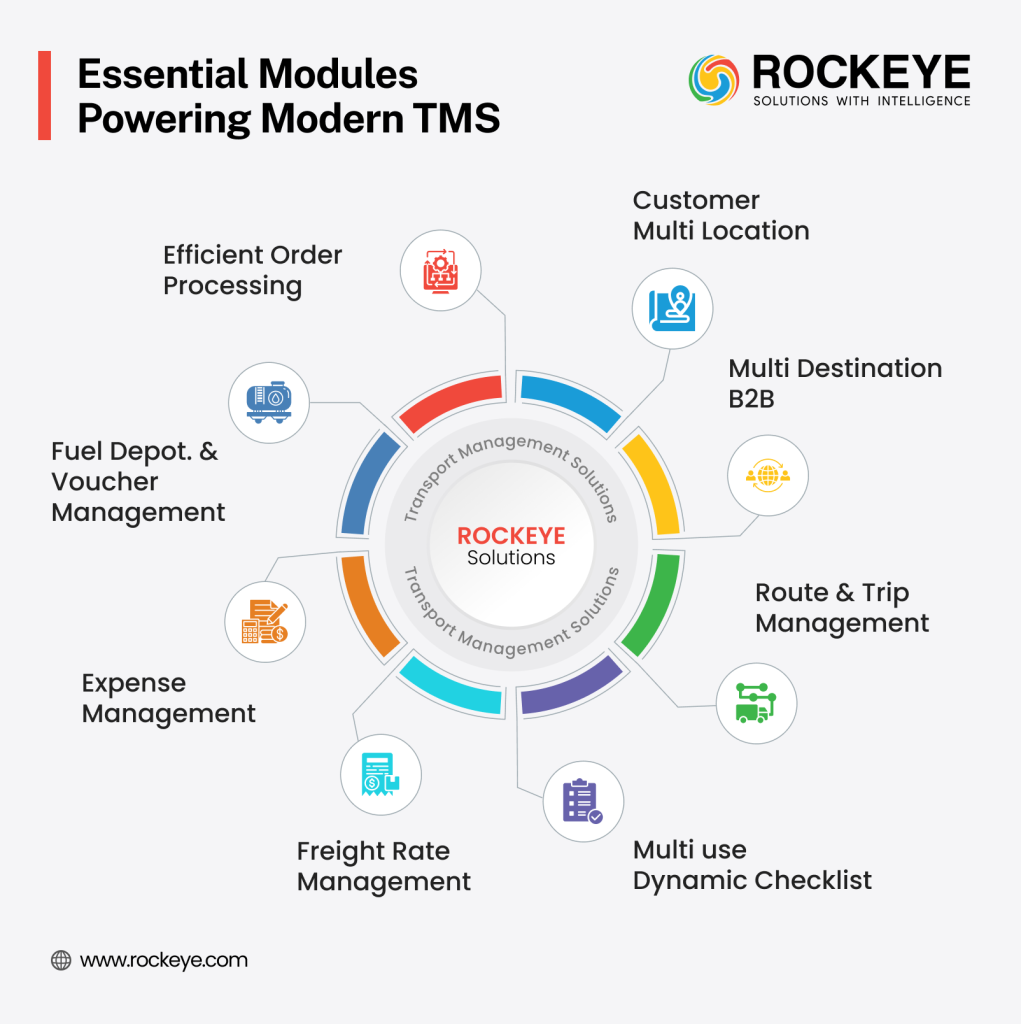

Key Functional Modules of an Effective TMS

A Transport Management System works best when every module solves real problems. The right TMS streamlines operations, improves visibility, and keeps control in your hands.

Efficient Order Processing

Manual entries slow operations. Automated order processing reduces turnaround time. Every order moves faster from request to dispatch. Real-time updates keep planners informed.

Customer Multi-location

Handling multiple sites can get messy. Multi-location management adapts to different client setups. You can manage several depots or outlets at once from a single dashboard.

Multi-destination B2B

B2B deliveries are complex with multiple drop points. Optimized multi-destination routing reduces distance, saves fuel, and meets timelines. Routes are calculated for maximum efficiency.

Route & Trip Management

Real-time tracking changes everything. Live GPS monitoring helps anticipate issues and reroute instantly. Routes adjust dynamically based on traffic, fuel usage, and delivery performance.

Multi-use Dynamic Checklist

Every transport job is different. Dynamic checklists adapt automatically to the task. They ensure every step is verified, improving accuracy and compliance on the ground.

Freight Rate Management

Freight pricing is often unpredictable. Automated freight rate management optimizes pricing, flags unprofitable routes, and ensures consistent margins.

Expense Management

Know where your money goes. You can track trip, vehicle, and office expenses per transporter. Visibility helps reduce waste and plan budgets more effectively.

Fuel Depot & Voucher Management

Fuel control drives profit. Depot-level fuel tracking and voucher management ensure transparency, prevent leakages, and keep stock reconciled in real time.

How TMS Inside an ERP Suite Creates Real Impact

In the fast-paced world of downstream logistics, efficiency hinges on seamless integration. An in-built TMS within your ERP suite isn’t just an add-on; it’s the backbone of synchronized operations.

Unified Data Flow for Real-time Decision-making

When your TMS is embedded within the ERP, data flows effortlessly between logistics, finance, and compliance modules. This ensures that once a delivery is completed, billing, fuel inventory, and payment schedules are updated automatically, eliminating manual interventions and reducing errors.

Streamlined Operations Across the Board

With the TMS operating within the ERP, logistics teams can plan routes, dispatch loads, and track performance in real time. Simultaneously, finance teams have immediate access to updated billing and inventory data, fostering better collaboration and quicker decision-making.

Enhanced Visibility and Control

This system provides a holistic view of operations. From tracking shipments to monitoring financial transactions, everything is accessible within a single platform, offering unparalleled transparency and control over your distribution network.

Scalability and Adaptability

As your operations grow, the in-built TMS within the ERP suite scales with you. Whether expanding to new regions or adapting to market changes, the unified system ensures consistent performance and adaptability without the need for complex integrations.

Why an ERP-powered TMS Works Better Than Standalone Solutions

Integrating a standalone TMS with ERP, terminal, and fleet systems can be tricky. Schema mismatches, clock drifts, API overload, and vendor lock-in often slow down operations and increase risk.

An in-built TMS embedded within your ERP suite avoids these pitfalls. Since it’s part of the same ecosystem, data flows seamlessly, real-time insights are reliable, and operational and financial processes are automatically synchronized.

Here’s a quick comparison:

| Factors | ERP-backed TMS | Standalone TMS |

|---|---|---|

| Data Consistency | Single source of truth; no schema mismatches | Risk of data errors; mapping needed |

| Real-time Visibility | Automatic updates across logistics, finance, compliance | Delays due to separate systems syncing |

| Operational Efficiency | Unified workflows, no manual interventions | Extra steps required to reconcile data |

| Scalability | Grows with ERP; plug-and-play for new modules | Integration required for expansion |

| System Reliability | Unified architecture avoids API throttling & clock drift | Vulnerable to overload and timestamp errors |

| Flexibility | Works with existing ERP/TMS; minimal vendor dependency | Often tied to specific vendors; harder to switch |

How ROCKEYE ERP Can Help You with Enterprise-grade TMS Implementation

At ROCKEYE, we know downstream logistics isn’t just about moving cargo, it’s about precision, visibility, and smarter decisions. Our AI-powered Transport Management System optimizes routes in real time, enhances logistics planning, and coordinates multi-terminal operations seamlessly: all without disrupting your existing workflows.

Conclusion

A modern, in-built TMS isn’t just a software upgrade; it’s a strategic advantage. Connecting data, people, and processes into a single intelligent flow helps downstream operators move faster, make smarter decisions, and stay ahead in an industry where every second and every barrel counts.

Frequently Asked Questions

1. What is an AI-powered TMS within ROCKEYE ERP?

An AI-powered TMS embedded in ROCKEYE ERP uses artificial intelligence and machine learning to optimize transport operations. It learns from past patterns, predicts demand, and suggests the best routes or schedules in real time: reducing fuel costs, eliminating delays, and enabling smarter logistics decisions.

2. How does ROCKEYE’s in-built TMS streamline multi-terminal operations?

With TMS fully integrated into ROCKEYE ERP, all terminal activities- from loading and storage to dispatch work- work in sync. Automated updates keep inventory, billing, and schedules accurate, while AI-powered insights optimize routes and fleet utilization, ensuring smooth, efficient downstream operations.

3. How does AI help optimize routes and reduce operational costs?

AI algorithms in ROCKEYE TMS analyze real-time traffic, vehicle location, and load patterns to recommend the most efficient routes. It reduces fuel consumption, minimizes idle time, and ensures timely deliveries across multi-terminal networks.

4. How does ROCKEYE TMS enhance decision-making for logistics managers?

With integrated dashboards, predictive analytics, and real-time alerts, managers can monitor fleet performance, anticipate delays, and make proactive decisions. Every delivery becomes an opportunity to improve efficiency, reduce costs, and maintain high service levels.