Summary:-

Inventory visibility gives your business real-time insight into stock levels at all possible locations, allowing you to prevent stockouts, reduce wastage, and meet growing expectations of customers with speed and accuracy. It turns your supply chain into an agile, well-oiled machine through a better order fulfillment process, enhanced demand forecasting, and reduced operational costs. Whether you are diversifying channels or ramping up existing ones, it ensures that the right products are always in the right place at the right time. Adopt inventory visibility to stay ahead of the competition and exceed customer expectation consistently.

Overview

Customer expectations keep evolving all the time. Whether it’s B2B clients expecting just-in-time inventory or consumers demanding same-day delivery, companies must operate with speed, precision, and transparency. So, inventory visibility is highly important to meet all the demands.

Inventory visibility means having real-time insight into stock levels across all warehouses, distribution centers, stores, and even in-transit shipments. It has become important to know different aspects of the stock, like:

- Where is it?

- How fast is it moving?

- What items need replenishing?

In this article, you will go through the major benefits of inventory visibility for your business.

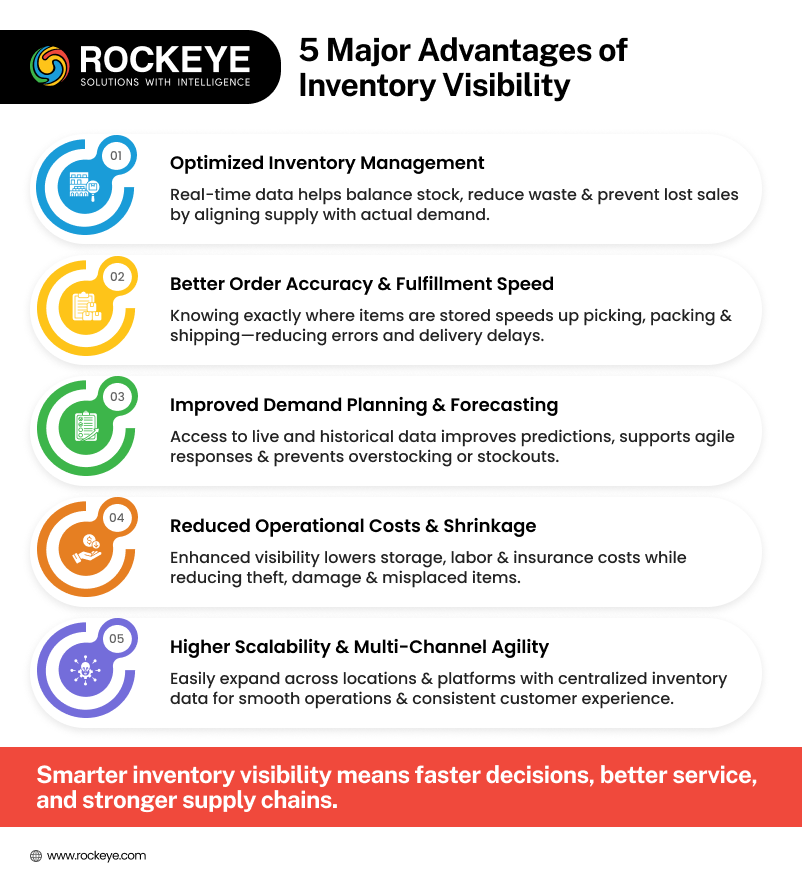

5 Major Advantages of Inventory Visibility

1. Optimized Inventory Management

Inventory visibility helps businesses in many ways, like:

- Optimize their stock levels

- Reduce waste

- Prevent lost sales

When you can see real-time data on every product in your supply chain, you can match stock with demand more precisely.

How it helps:

- Reduces stockouts: Knowing exactly when and where inventory is low allows for proactive replenishment.

- Minimizes overstocking: Avoid holding excess stock that ties up capital and increases storage costs.

- Supports demand forecasting: Historical and live data helps predict future demand patterns more accurately.

A retailer with strong inventory visibility can adjust inventory allocation between stores and warehouses in a dynamic manner. It enables faster turnover and lower holding costs. This visibility is critical for businesses with seasonal inventory or fast-changing SKUs.

When businesses utilize the benefits of inventory visibility, inventory control becomes efficient, predictive, and customer-focused.

2. Better Order Accuracy and Fulfilment Speed

Inventory errors result in incorrect orders, delayed shipments, and unhappy customers. Real-time inventory visibility allows fulfilment centres to process orders with higher accuracy and speed.

Key advantages:

- Improved order picking: Warehouse staff can pick the right items faster when they know exactly where the stock is located.

- Smarter routing: Orders can be routed to the closest fulfilment centre with available stock, reducing delivery time and shipping costs.

- Automated updates: With integrated systems, customers receive automatic order status updates, reducing calls to customer service.

Consider an eCommerce brand operating multiple fulfilment centres. If there is a lack of inventory visibility, then the order may be delayed or misrouted. However, with a solid central system in place, you can allocate orders in the most efficient location. This will allow your business to cut down on last-mile delivery costs and improve delivery times.

3. Improved Demand Planning And Forecasting

It is important to have precise forecasting to avoid costly inventory mishaps. A poor level of prediction can lead to the event of excess stock or stockout. Inventory visibility feeds demand planning tools with real-time, accurate data, which further improves their effectiveness.

Why it matters:

- Data driven forecasting: Instead of relying on historical trends alone, you gain insights from current inventory turnover rates, returns, and regional demand shifts.

- Cross-functional insights: Sales, operations, and procurement teams can collaborate using a single source of truth.

- Agility during market shifts: During unexpected surges (think COVID-19 or Black Friday), inventory visibility helps businesses adapt fast.

When planners can trust the data they’re working with, they can make smarter decisions. This reduces the bullwhip effect, where small demand fluctuations cause major supply chain disruptions.

4. Reduced Operational Costs And Inventory Shrinkage

You have to keep in mind that there are many costs that can cut down your margins, like:

- Storage costs

- Insurance

- Inventory carrying costs

Also, the lack of visibility can lead to inventory shrinkage due to theft, damage, or misplacement.

How visibility helps cut costs:

- Better space utilization: Knowing your actual inventory levels helps optimize warehouse layout and slotting.

- Lower labor costs: Staff spend less time searching for misplaced items or double checking stock.

- Shrinkage reduction: Real time tracking allows for faster detection of anomalies or discrepancies, deterring theft and minimizing losses.

According to the National Retail Federation, shrinkage costs U.S. retailers nearly $100 billion annually. Inventory visibility systems with advanced tools like IoT sensors, barcode scanning, etc., can help identify where, when, and why shrinkage is occurring.

5. Higher Scalability And Multi-Channel Agility

When your business grows, you have to add new warehouses, channels, product lines, etc. So, it becomes critical to ensure proper visibility across all these things. Scaling can lead to a lot of chaos without a clear view of stock across locations and platforms.

Inventory visibility enables:

- Seamless multi-channel fulfilment: Whether it’s online, in-store, or click-and-collect, inventory can be sourced intelligently across channels.

- Easier expansion: New warehouses or stores can be integrated into the existing inventory system with minimal disruption.

- Unified customer experience: Real time inventory updates ensure consistent product availability across all customer touchpoints.

For example, when a business is expanding to global markets, it is important to have visibility into the SKUs that are selling quickly. Without this information, your supply chain may suffer delays and inefficiencies. However, when the inventory data is centralised, businesses can scale quickly and confidently.

Why Now? The Urgency for Real Time Inventory Visibility

The rise of same day delivery, omnichannel retail, and lean inventory models has made real-time inventory visibility more than a nice-to-have. It’s a necessity.

Legacy systems and spreadsheets simply can’t keep up with the demands of modern logistics. Companies need connected, cloud-based solutions with advanced features like:

- Real time inventory updates that support automation

- AI-based forecasting

- End to end supply chain transparency

Here are all the details of the urgency:

- Omnichannel pressure: Customers shop across websites, apps, and physical stores. Real-time visibility ensures accurate stock counts across all platforms, preventing overselling or lost sales.

- Rising customer expectations: Consumers expect fast, accurate fulfilment. Visibility empowers faster order processing, smarter routing, and live order tracking, all of which boost satisfaction.

- Supply chain volatility: From global disruptions to local delays, modern supply chains face constant uncertainty. Inventory visibility provides the transparency needed to pivot quickly and minimize impact.

- Lean inventory models: Businesses are shifting away from overstocking to reduce costs. Real-time data supports just-in-time replenishment and leaner, more agile operations.

- Tech advancement: Affordable tools like cloud-based inventory software, IoT devices, and AI-driven analytics make real-time tracking accessible, even for smaller businesses.

- Competitive edge: Companies with strong inventory visibility outperform slower rivals. They move faster, fulfill accurately, and scale efficiently.

Conclusion

Inventory visibility has become an important part of businesses to enjoy smarter warehousing and fulfillment. When you can see what you have, where it is, and how it moves, your business becomes faster, more accurate, and more efficient. From better customer satisfaction to lower costs and improved forecasting, there are many benefits of inventory visibility. It helps you avoid stockouts, reduce waste, and make confident decisions in real-time. Whether you’re running a small business or a large operation, investing in inventory visibility sets you up for long-term success. ROCKEYE offers top-notch tools with which you can enjoy better visibility for your inventory and improve your overall supply chain. Call them today to get all the details.

FAQs

Q1. What technologies are used to achieve inventory visibility?

Here are the top technologies that allow real-time tracking and visibility across the supply chain.:

- RFID

- Barcode scanning

- IoT sensors

- WM

- ERP systems

- Cloud-based inventory platforms

Q2. Can small businesses benefit from inventory visibility tools?

Yes, small retailers can implement cloud-based inventory tools that offer real-time tracking. It will help them to compete with larger players and streamline their fulfilment processes.

Q3. How does inventory visibility help reduce shrinkage?

It helps identify discrepancies quickly, monitor high-risk areas, and track item movement in real time. On top of this, it makes it easier to catch theft, misplacement, or damage early.

Q4. Is inventory visibility only important for e-commerce businesses?

No. While eCommerce heavily relies on it, manufacturers, wholesalers, and brick-and-mortar retailers also benefit from improved accuracy, planning, and reduced overhead.

Q5. How long does it take to implement an inventory visibility solution?

The overall implementation time will depend on the complexity and size of your operation. A basic cloud inventory system can be up and running in a few weeks, while enterprise-level integrations may take several months.