Fuel businesses across Kenya, Malaysia, and Indonesia are operating in one of the most complex commercial environments in the world. Margins are tightening. Regulatory oversight is increasing. Supply chains are expanding across borders, depots, fleets, and dealer networks. Yet many fuel organizations are still managing critical commercial operations through fragmented fuel control systems, disconnected industrial control systems, and manual reconciliations.

If you are a C-suite leader, the challenge is no longer automation alone. The real challenge is commercial control at scale.

A unified control suite has emerged as the strategic backbone for global fuel leaders who want predictable margins, audit-ready operations, and real-time visibility across the fuel supply chain.

This article explains why unified control architectures are becoming essential, how they differ from traditional distributed control systems, and how you can use them to build a future-ready operational excellence platform.

Also read: How Predictive Maintenance Reduces Fuel Station Downtime and Improves Asset Uptime

The Growing Complexity of Modern Fuel Operations

Fuel businesses today are no longer linear operations. They are interconnected ecosystems that span refineries, terminals, transport fleets, dealer networks, and financial systems.

Across emerging fuel markets like Kenya, Malaysia, and Indonesia, leadership teams are facing common challenges:

- Revenue leakage due to manual reconciliation between depots, fleets, and sales channels

- Limited visibility into real-time stock, pricing, and margin performance

- Fragmented fuel supply chain management systems that do not talk to each other

- Compliance risks driven by inconsistent data across operational and financial layers

- Delayed decision-making due to retrospective reporting rather than real-time control

Traditional industrial automation control was designed to manage physical processes. It was not designed to manage commercial risk, pricing discipline, or margin governance.

That gap is where unified control suites are redefining how fuel leaders operate.

What Is a Unified Control Suite in Fuel Operations?

A unified control suite is an integrated commercial and operational control layer that connects industrial control systems, fuel control units, fleet systems, inventory platforms, and financial workflows into one governed architecture.

Unlike standalone fuel control systems or isolated distributed control systems, a unified control suite aligns physical fuel movement with commercial accountability.

Core Characteristics of a Unified Control Architecture

- Centralized visibility across the entire fuel supply chain

- Real-time reconciliation between fuel movement and financial records

- Embedded governance for pricing, contracts, and margin protection

- Automated controls across terminals, fleets, and dealer networks

- Decision-ready intelligence for leadership teams

For fuel leaders, this is not about replacing existing automation. It is about orchestrating control across systems that already exist.

Why Industrial Control Systems Alone Are No Longer Enough

Industrial control systems and distributed control systems play a critical role in refinery and terminal operations. They ensure safety, throughput, and process reliability. However, they operate primarily at the physical layer.

What they do not solve:

- Commercial reconciliation across locations

- Contract compliance across suppliers and distributors

- Margin leakage caused by pricing mismatches

- Fuel theft, pilferage, or undocumented variances

- End-to-end fuel supply chain visibility

This is why global fuel companies are complementing industrial automation control with unified commercial control platforms.

The objective is simple. Every liter moved must be commercially accountable.

Unified Control Suite as an Enterprise Automation Strategy

For C-suite leaders, a unified control suite is not a software purchase. It is an enterprise automation strategy that aligns operations, finance, and governance under a single control framework.

How It Transforms Decision-making

- Moves leadership from lagging reports to real-time control

- Enables proactive intervention instead of post-period corrections

- Creates a single source of truth across operational and financial data

- Strengthens board-level confidence in reported margins

When deployed correctly, a unified control suite becomes the operational excellence platform that leadership teams rely on to protect profitability.

Also read: Boost Fuel Retail Margins by 15–25% with Integrated Downstream Commercial Control.

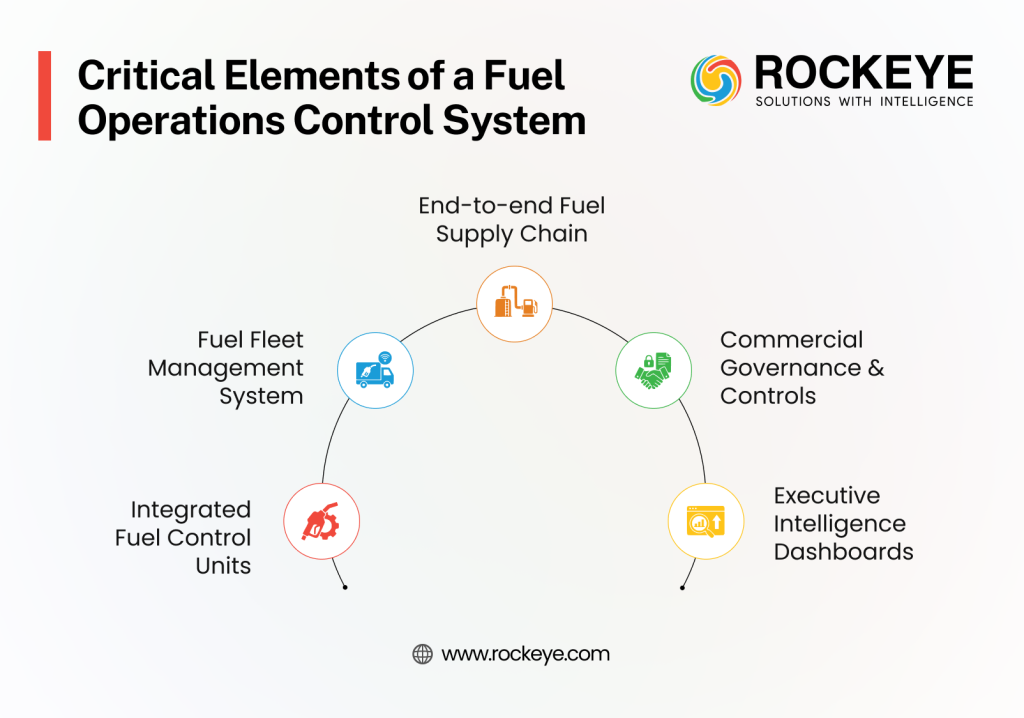

Key Components of a Unified Control System for Fuel Operations

1. Integrated Fuel Control Units and Terminal Systems

At the ground level, fuel control units capture precise data on fuel intake, storage, and dispatch. A unified control suite consolidates this data across terminals and depots, eliminating blind spots between locations.

2. Fuel Fleet Management System Integration

Fuel losses often occur in transit. By integrating fleet telemetry, dispatch data, and consumption records, unified control systems ensure fuel moved is the fuel delivered.

Fuel fleet management system is especially critical in markets like Kenya and Indonesia, where long-distance logistics increase exposure to leakage.

3. End-to-end Fuel Supply Chain Management

Unified control platforms link upstream procurement with downstream sales, ensuring that pricing, volume, and margin expectations remain aligned throughout the fuel supply chain.

4. Commercial Governance and Margin Controls

This layer enforces pricing rules, contract terms, tax logic, and margin thresholds automatically. Deviations trigger alerts, not surprises during audits.

5. Executive Intelligence and Control Dashboards

Leadership teams gain access to real-time KPIs across operations, finance, and risk. It replaces fragmented reporting with decision-grade intelligence.

Why Global Fuel Companies Are Moving Toward Unified Control Architectures

Fuel leaders across Southeast Asia and East Africa are under pressure to scale without increasing risk.

Unified control architectures are gaining traction because they:

- Reduce revenue leakage across depots and fleets

- Strengthen audit readiness and regulatory compliance

- Improve pricing discipline in volatile markets

- Enable faster month-end and year-end closures

- Support multi-country operational governance

In Malaysia and Indonesia, where dealer networks are extensive, unified control ensures consistent commercial practices across regions. In Kenya, where regulatory scrutiny is rising, it strengthens compliance without slowing operations.

Supporting Digital Transformation in the Fuel Industry

Digital transformation in fuel operations is often misunderstood as digitizing reports or deploying new ERP modules.

Unified control suites take a different approach.

They focus on digitizing control, not just data.

By connecting industrial control systems, fuel control units, and commercial workflows, unified platforms create an integrated automation solution that supports:

- Real-time operational governance

- Predictive decision-making

- Scalable expansion into new markets

- Controlled integration with existing ERPs

This approach ensures that automation directly improves margins and reduces risk.

Predictive Maintenance Through Unified Control Platforms

While predictive maintenance is traditionally associated with industrial automation control, unified control platforms enhance its commercial value.

How Predictive Maintenance Improves Commercial Outcomes

- Equipment downtime is linked to revenue impact, not just operational metrics

- Maintenance schedules align with supply commitments and demand forecasts

- Asset performance data feeds financial planning and risk models

- For fuel leaders, this means fewer disruptions, better asset utilization, and improved profitability.

How ROCKEYE Powers Unified Commercial Control for Fuel Leaders

ROCKEYE is not an ERP replacement. It is the industry’s purpose-built Commercial Control System for downstream fuel and energy operations, also known as DCCS.

ROCKEYE sits above existing industrial control systems and ERPs, acting as the unified control layer that governs commercial outcomes.

What You Can Achieve with ROCKEYE

- End-to-end control across terminals, fleets, and dealer networks

- Automated reconciliation that eliminates manual errors

- Real-time margin visibility across the fuel supply chain

- Embedded audit controls aligned with regional regulations

- Scalable architecture for multi-country fuel operations

For fuel businesses in Kenya, Malaysia, and Indonesia, ROCKEYE delivers measurable results:

- Reduced leakage across fuel movements

- Tighter pricing and margin governance

- Faster financial closures with higher confidence

- Improved compliance without operational friction

When you work with ROCKEYE, you gain a strategic backbone that protects profitability while enabling growth.

Conclusion: Control Is the New Competitive Advantage

Fuel markets are becoming more competitive, more regulated, and more volatile. Growth without control is no longer sustainable.

A unified control suite provides the structure, visibility, and governance that modern fuel leaders need to operate with confidence.

If your organization is still relying on fragmented fuel control systems and disconnected industrial automation control, the risk is not theoretical. It is already impacting margins.

Unified control is no longer optional. It is the foundation of long-term leadership in global fuel operations.

Frequently Asked Questions

How does a unified control suite improve operational efficiency in fuel refineries?

A unified control suite connects refinery operations with commercial systems, enabling real-time reconciliation between production, storage, and dispatch. It reduces manual interventions, shortens decision cycles, and ensures that operational efficiency directly translates into financial performance.

What are the core components of a unified control system for fuel operations?

Core components include integrated fuel control units, fleet management systems, fuel supply chain management, commercial governance controls, and executive intelligence dashboards. Together, these components create end-to-end visibility and accountability.

Why are global fuel companies moving toward unified control architectures?

Global fuel companies adopt unified control architectures to reduce revenue leakage, strengthen compliance, improve margin discipline, and scale operations across regions without increasing risk. Unified control enables consistent governance across complex fuel networks.

How do unified control suites support digital transformation in the fuel industry?

Unified control suites support digital transformation by embedding governance, automation, and intelligence into daily operations. Instead of digitizing reports, they digitize control, ensuring that every transaction is auditable, compliant, and margin-protected.

How do unified control platforms support predictive maintenance in fuel operations?

Unified control platforms integrate asset performance data with commercial intelligence. It allows maintenance decisions to consider revenue impact, supply commitments, and operational risk, resulting in fewer disruptions and better asset utilization.