Why Supply‑Chain Optimization Matters Today

For manufacturers operating in markets like Indonesia, Malaysia, Vietnam, the UAE, Saudi Arabia, Kenya, or Ghana, every minute of downtime, every batch delay, and every mismanaged raw material order can ripple across cost, delivery commitments, and customer trust. In an era where demand fluctuates rapidly and competition is global, having a responsive digital manufacturing & supply‑chain backbone is no longer optional.

A robust manufacturing supply chain with real-time visibility, from procurement to production to dispatch, is what separates lean, profit-driven operations from reactive, crisis-driven ones.

This is the story of how a premium carbon-steel manufacturer transformed its operations and reduced line stoppages by 12% by adopting a digital, end-to-end supply-chain solution from ROCKEYE.

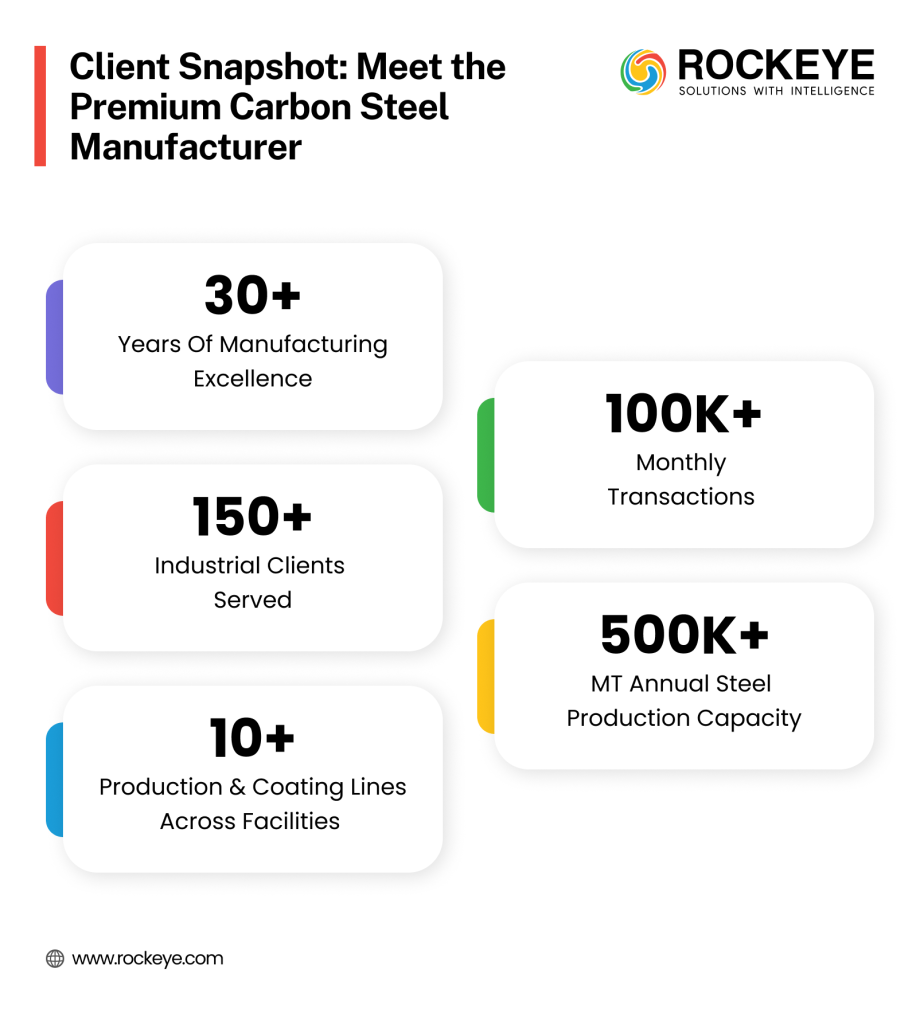

Client Snapshot: Meet the Premium Carbon Steel Manufacturer

Our client is a well‑established carbon‑steel producer with deep expertise and scale: a company that invests heavily in quality, technology, and R&D, building flat carbon‑steel products through hot strip milling, cold rolling, and hot‑dip coating lines.

Key facts about the client:

- Over 30 years of manufacturing excellence

- Handles 100,000+ monthly transactions across operations.

- Serves 150+ industrial clients and delivers 500,000+ metric tons annually across multiple production and coating lines.

Essentially, large-scale, complex operations, heavy throughput, and many moving parts. But with size and complexity came operational strain.

The Challenges: What Was Holding Them Back

As a high-precision steel manufacturer covering procurement, production, warehousing, finance, and sales, our client faced several challenges that undermined efficiency.

- Lack of real‑time cross‑department visibility in procurement, production, inventory, and outbound logistics was managed in silos.

- Fragmented order, material consumption, and batch production tracking make it difficult to synchronize supply, usage, and output across plants.

- Need for a modular, customizable ERP / supply‑chain solution. Off-the-shelf legacy ERPs lacked flexibility, and frequent changes in production patterns demanded agility.

- With demand for rapid deployment with minimal IT overhead, the business could not afford months‑long deployments or heavy maintenance burdens.

- Disjointed workflows across finance, HR, production, and compliance often leave critical operations such as payroll, vendor management, sales, and financial reporting fragmented, causing inefficiencies, errors, and delayed decision-making.

- Advanced reporting and analytics for agile decision‑making leadership needed real-time, reliable data to drive procurement, production scheduling, and dispatch decisions.

In summary, traditional systems could not manage the complexity, scale, and constant changes. This increases the risks of delays, material mismanagement, and inefficiency.

How ROCKEYE Provided the Solution

The company chose ROCKEYE’s Manufacturing Suite, a modular, web and mobile‑enabled digital platform to transform its manufacturing supply chain management, streamline operations end-to-end, and establish real‑time visibility across departments.

Modules & Features Implemented

ROCKEYE deployed a full stack of modules to cover all business functions under one unified system:

- Production management solution to manage production lines, batch processing, and coating operations.

- Inventory & Warehouse solution for inventory tracking, raw material planning, and warehouse management.

- Procurement software solution to synchronize raw material purchases with production demand and supplier management.

- Sales & Invoicing to manage customer orders, dispatch schedules, and invoicing linked to production outcomes.

- Financial Accounting to integrate financial operations, cost centers, and financial reporting with production & procurement.

- Human Resources Management to manage workforce, HR workflows, and payroll seamlessly integrated with production and supplier operations.

Because the platform is SaaS and modular, it also allows integration with legacy systems and third‑party applications, while enabling remote, multi‑user access, real-time process visibility, and minimal IT maintenance overhead.

Moreover, the system was configurable, enabling the manufacturer to tailor workflows, approvals, vendor/contractor coordination, and production‑batch tracking as per their unique requirements.

Also Read: Integrated Supply Chain Visibility for Manufacturing Plants – Inbound + Outbound Control

Implementation & Change Management

One of the striking advantages was speed and agility: deployment and configuration of ROCKEYE’s suite took weeks instead of months, far faster than heavy legacy ERPs.

During rollout, the manufacturer tested the configuration, ensured that batch flows matched their process logic, and integrated supplier and vendor workflows. The flexibility of ROCKEYE allowed them to provide feedback, which was incorporated into subsequent updates, making the implementation more collaborative and tailored

Cross-department coordination from procurement to production to finance and HR became much simpler as all functions moved under one digital umbrella.

In the words of their technical lead:

“We use the software to authenticate deliveries, track production batches, manage financial records, and oversee HR workflows all within ROCKEYE’s user‑friendly interface. Now, it’s the backbone of our plant’s digital operations.”

Outcomes: What Changed — Efficiency, Clarity, Control

With ROCKEYE’s Manufacturing Suite live, the manufacturer gained:

- Accurate inventory reconciliation and production tracking, hundreds of items managed with consistency across plants.

- Smart batch scheduling with full traceability, from raw material receipt to final dispatch, makes every batch’s lifecycle visible.

- Handling of 100,000+ monthly transactions across modules, demonstrating the system’s robustness under real-world load.

- Real-time visibility and control from procurement to dispatch, enabling better procurement planning, reducing idle inventory, and avoiding stock-outs.

- Streamlined automation of HR, Finance, and Sales workflows, reducing manual overhead, errors, and coordination delays.

- Enhanced planning, compliance, and traceability are crucial for a manufacturer dealing with stringent quality standards.

- 12% reduction in line stoppages across production lines

While the original case‑study highlights “speed & precision” improvements, and “cross‑departmental efficiencies,” these translate in manufacturing supply chain terms into: fewer stoppages, better material management, and smoother coordination.

The implementation’s fast turnaround and adaptability meant that the company could scale production and operations without being bogged down by system limitations, a crucial advantage for manufacturers aiming to expand or serve multiple geographies.

What This Means for Manufacturing & Supply‑Chain Leaders Across Regions

For CFOs, COOs/Operations Heads, Procurement and Plant Directors in Indonesia, Malaysia, Vietnam, UAE, Saudi Arabia, Kenya, Ghana, this case study offers a replicable blueprint:

- When your manufacturing supply chain spans procurement → production → warehousing → sales → finance → HR, it’s critical to unify those functions for real‑time visibility and control.

- Legacy ERPs and fragmented systems introduce friction, hidden costs, and risk of delays, especially across complex operations like steel production.

- A modular, digital, cloud‑based supply‑chain + manufacturing solution brings agility, traceability, and scalability, enabling manufacturers to grow without growing complexity.

- Rapid deployment and minimal maintenance overhead make digital transformation viable even for companies that can’t afford long project cycles.

- Complete integration from batch-level production tracking to finance and HR workflows ensures that all departments work with the same data, enhancing collaboration and reducing silos.

In short, digital supply‑chain transformation is not “nice to have,” it’s a critical competitive lever.

Conclusion: From Complexity to Control — The Supply‑Chain Transformation

The premium carbon‑steel manufacturer’s journey from fragmented operations to a unified, digital, and automated manufacturing supply chain is a strong testament to the power of integrated Cloud ERP Systems + supply‑chain platforms. With ROCKEYE, they achieved operational clarity, production stability, and process agility essentials for any manufacturer aiming for growth across emerging markets or global supply chains.

For manufacturing leaders, especially in high-volume, complex operations, the message is clear:

Optimize your supply chain. Digitize your production flow. Unify your data. Control your destiny.

If you want to explore what a similar transformation could look like for your setup, scaled to your region, consider booking a consultation with ROCKEYE.

FAQs

Curious about how digital supply-chain solutions can reduce production downtime? Explore these top questions and answers to see how manufacturers are achieving smoother operations and fewer line stoppages.

1. How can a digital manufacturing supply chain reduce line stoppages by 10–15%?

A digital manufacturing supply chain reduces line stoppages by providing real‑time visibility, predictive alerts, and integrated workflows across procurement, production, inventory, and dispatch. By tracking raw materials, machine status, and production batches in a unified system, manufacturers can anticipate shortages or equipment issues, schedule preventive maintenance, and avoid reactive downtime. Such improvements typically yield 10–15% fewer unplanned stoppages, faster throughput, and smoother production flow, especially for complex, high‑volume plants where manual systems or silos trigger delays.

2. What are the key modules/components needed to cut line stoppages in a steel manufacturing supply chain?

To reduce line stoppages in a steel manufacturing supply chain, a robust digital solution should include:

- Production module for line monitoring, batch scheduling, and machine downtime detection.

- Inventory & Warehouse module to ensure raw material availability and avoid stockouts that pause production.

- The procurement module synchronizes procurement with production demand, so supply aligns with consumption.

- Integrated Finance / ERP / HR / Sales modules to ensure all departments work with the same data, reducing coordination delays.

- Real-time analytics & reporting enabling early detection of bottlenecks, trends, and potential disruptions.

This end-to-end integration transforms fragmented operations into a unified, responsive manufacturing supply chain.

3. What supply chain challenges typically cause line stoppages in large‑scale manufacturing plants?

In large-scale manufacturing, common causes of production line stoppages include:

- Material shortages due to poor procurement–inventory coordination

- Fragmented visibility across departments (procurement, production, warehouse, dispatch).

- Lack of real-time tracking of batches and machine uptime is causing delays or unexpected downtime.

- Legacy ERP or siloed systems delay communication and slow decision‑making.

- Manual workflows and a lack of automated alerts for delays or quality issues.

Addressing these challenges requires a holistic, integrated supply chain + manufacturing management system.

4. Why should CIOs/CFOs in Southeast Asia or the Middle East consider digital supply‑chain transformation for manufacturing?

For manufacturing leaders, especially in regions like Indonesia, Malaysia, Vietnam, UAE, Saudi Arabia, Kenya, Ghana, digital supply‑chain transformation offers:

- Reduced downtime & stoppages, directly improving output and margins.

- Better supply and demand alignment across procurement, production, inventory, and sales is essential when dealing with volatile demand or raw‑material sourcing.

- Scalability and agility — modular, SaaS‑based systems allow expansion across plants without huge IT overhead.

- Transparency and compliance — integrated workflows ensure consistent tracking, traceability, and easier audits.

- Data‑driven decision‑making and real‑time analytics help CFOs and COOs spot inefficiencies, manage costs, and plan investments confidently.

Overall, the ROI often comes from fewer stoppages, higher throughput, and lower carrying/idle costs.

5. What measurable benefits (KPIs) can manufacturing companies expect after implementing an integrated supply‑chain solution?

After implementing an integrated manufacturing supply‑chain solution, companies can typically measure improvements in:

- Line‑stoppage reduction (e.g. → 10–15% fewer unplanned downtimes)

- Throughput/output increase (higher units produced per time)

- Inventory turns and reduction in idle/holding inventory (better raw‑material utilization)

- Improved order fulfillment / on‑time delivery rate (due to synchronized production and dispatch)

- Reduced manual overhead / administrative delays, fewer human errors, faster approvals, and dispatch cycles

- Real‑time visibility & traceability across batches, helping with quality control, compliance, and audit readiness

These KPIs align with core manufacturing supply chain goals: efficiency, cost control, agility, and reliability.