Fuel stations are the lifeblood of modern mobility, and keeping them operational 24/7 is critical for both customer satisfaction and revenue generation. However, equipment failures and unplanned downtime can have severe consequences for fuel station operators. From malfunctioning pumps to faulty dispensers, even short interruptions can result in lost sales, frustrated customers, and higher maintenance costs.

This is where predictive maintenance comes in, a proactive approach that helps fuel stations minimize downtime, optimize asset performance, and enhance operational efficiency. In this article, we explore how predictive maintenance works, its benefits, and how advanced fuel station management systems can make it easier to implement.

Understanding Predictive Maintenance in Fuel Stations

Predictive maintenance is a maintenance strategy that uses real-time data, machine learning, and condition monitoring to predict equipment failures before they occur. Unlike reactive maintenance, which only addresses breakdowns after they happen, or preventive maintenance, which relies on scheduled servicing, predictive maintenance focuses on anticipating issues and intervening at the right moment.

In the context of fuel stations, predictive maintenance can monitor pumps, dispensers, storage tanks, payment terminals, and other critical equipment to detect anomalies early. This proactive approach ensures that minor issues are addressed before they escalate into costly downtime, helping operators reduce equipment downtime and improve overall efficiency.

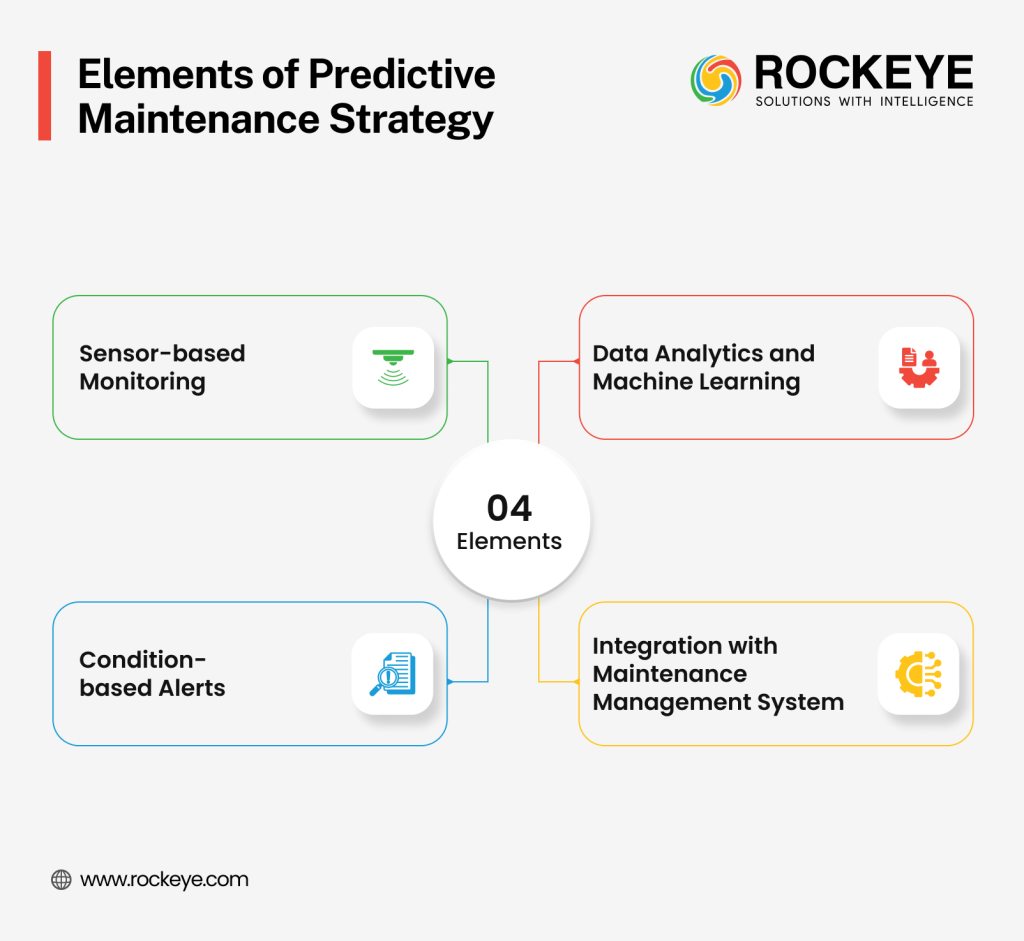

Key Components of Predictive Maintenance Strategy

Implementing a successful predictive maintenance strategy requires a combination of technologies and methodologies. Some of the key components include:

1. Sensor-based Monitoring

Sensors track critical parameters such as vibration, temperature, pressure, and flow rates. For fuel pumps, for instance, monitoring vibration and flow consistency can

2. Data Analytics and Machine Learning

Advanced analytics tools process sensor data to detect patterns, anomalies, and trends that may signal impending failure. Machine learning models can learn from historical equipment data to predict future maintenance needs.

3. Condition-based Alerts

Predictive maintenance relies on real-time alerts triggered by changes in equipment conditions. These alerts allow maintenance teams to take timely action, preventing breakdowns.

4. Integration with Maintenance Management Systems

A fuel station management system or fuel station management software integrates predictive insights with maintenance workflows, enabling scheduling, documentation, and reporting for all maintenance activities.

Predictive Maintenance Benefits for Fuel Stations

Adopting predictive maintenance offers numerous benefits for fuel station operators, including:

1. Reduced Unplanned Downtime

Predicting failures before they occur ensures that fuel pumps and dispensers remain operational, minimizing lost sales opportunities.

2. Lower Maintenance Costs

Addressing minor issues early reduces the need for costly emergency repairs and prevents secondary damage to equipment.

3. Improved Equipment Reliability

Regular monitoring and proactive maintenance enhance the equipment reliability improvement, ensuring fuel pumps, storage tanks, and dispensers operate at peak performance.

4. Extended Asset Lifespan

Predictive maintenance helps protect expensive equipment by avoiding stress and wear from undetected faults.

5. Enhanced Customer Satisfaction

Reliable equipment means customers experience fewer disruptions, shorter wait times, and consistent fuel availability.

6. Optimized Resource Allocation

Maintenance teams can plan interventions more effectively, reducing labor inefficiencies and unnecessary part replacements.

Reliability-centered Maintenance and Industrial Equipment Maintenance

Fuel stations operate in complex environments with numerous interconnected systems. To manage these effectively, many operators adopt reliability-centered maintenance (RCM), which prioritizes maintenance based on the criticality and failure risks of each asset.

Industrial equipment maintenance practices such as lubrication management, periodic inspections, and calibration are often combined with predictive maintenance to maximize uptime. RCM ensures that critical assets like fuel dispensers and storage tanks receive focused attention, while less critical equipment is maintained on a cost-effective schedule.

Maintenance Optimization Strategies

Successful maintenance optimization strategies combine predictive analytics with operational best practices:

1. Risk-based Prioritization

Evaluate the consequences of equipment failure and prioritize maintenance for assets that have the highest impact on operations.

2. Historical Performance Analysis

Analyze historical downtime data to identify recurring failure patterns and plan interventions more effectively.

3. Condition-based Scheduling

Move away from fixed schedules and adopt condition-based interventions based on equipment health metrics.

4. Continuous Improvement Loops

Regularly review maintenance KPIs and predictive insights to refine processes, reduce errors, and enhance overall equipment efficiency.

These strategies are particularly relevant in the fuel station market, where equipment failures can directly impact revenue, safety, and customer loyalty.

How Predictive Maintenance Reduces Fuel Station Downtime

By combining monitoring, predictive analytics, and timely interventions, predictive maintenance reduces fuel station downtime in several ways:

- Early Fault Detection: Sensors identify issues such as pump misalignment, pressure fluctuations, or dispenser wear before they cause a breakdown.

- Minimized Emergency Repairs: With alerts and scheduled interventions, maintenance teams can address problems without disrupting daily operations.

- Optimized Spare Parts Management: Knowing in advance which components may fail helps maintain optimal inventory levels for replacement parts.

- Increased Operational Visibility: Fuel station managers can track equipment performance in real time, ensuring informed decisions.

Ultimately, these measures help improve asset uptime, ensure consistent fuel availability, and enhance overall operational efficiency.

Predictive Maintenance in Oil and Gas

The oil and gas industry has embraced predictive maintenance for its upstream, midstream, and downstream operations. For fuel retail operations, predictive maintenance helps:

- Ensure pumps, dispensers, and storage tanks are always operational.

- Reduce downtime caused by equipment failure or regulatory compliance issues.

- Support maintenance optimization strategies that improve operational resilience.

Using predictive maintenance in fuel stations is part of a broader strategy to modernize operations, enhance safety, and deliver reliable customer service.

How ROCKEYE Can Help

Implementing predictive maintenance effectively requires smart tools that integrate monitoring, analytics, and workflow management. ROCKEYE’s smart fuel station management solution provides a comprehensive platform for fuel station operators to monitor equipment health, schedule maintenance, and optimize operations in real time.

Key benefits of ROCKEYE’s smart solution include:

- Real-time monitoring of pumps, dispensers, and storage tanks.

- Predictive alerts for equipment faults before they escalate.

- Maintenance scheduling integrated with operational workflows.

- Comprehensive reporting and analytics for continuous improvement.

By leveraging ROCKEYE, fuel stations can maximize uptime, reduce equipment downtime, and achieve measurable gains in efficiency and customer satisfaction.

Fuel Station Management Software and Systems

A modern fuel station management system or fuel station management software combines predictive maintenance with operational management. Key features include:

- Inventory and stock tracking

- Pump and dispenser monitoring

- Automated maintenance alerts

- Compliance reporting

- Integration with point-of-sale and financial systems

These systems ensure that fuel stations not only operate efficiently but also meet regulatory requirements and maintain high equipment reliability.

Conclusion

Predictive maintenance is transforming how fuel stations operate by shifting from reactive repairs to proactive management. By monitoring equipment health, analyzing performance trends, and implementing timely interventions, operators can significantly reduce downtime, enhance equipment reliability, and ensure consistent customer service.

Combining predictive maintenance with a robust fuel station management system or fuel station management software, such as ROCKEYE’s smart solutions, empowers operators to streamline operations, optimize maintenance workflows, and safeguard revenue in a competitive fuel station market.

FAQs

1. How can fuel stations improve asset uptime?

Fuel stations can improve asset uptime through predictive maintenance, real-time equipment monitoring, and timely interventions based on data-driven insights.

2. What maintenance strategies are best for fuel station equipment?

A combination of reliability-centered maintenance, condition-based monitoring, and predictive maintenance strategies is most effective for fuel stations.

3. How does downtime impact fuel pump availability and sales?

Downtime directly reduces pump availability, leading to lost sales, customer dissatisfaction, and increased operational costs.

4. How can real-time monitoring prevent fuel station downtime?

Real-time monitoring detects early warning signs of equipment failure, allowing maintenance teams to intervene before downtime occurs.

5. How do oil and gas companies manage downtime in fuel retail operations?

Companies use predictive maintenance, integrated management systems, and optimized maintenance schedules to reduce downtime and enhance operational efficiency.