The Silent Margin Crisis in Indonesia’s Fuel Depots

Indonesia’s downstream market runs on micro-margins. Any delay in pricing, miscalculated density, missed freight charges, or incorrect contract rules instantly erodes margins, often without anyone noticing. Most depots do not lose profit due to competitors; they lose it because of invisible commercial leaks within their daily operations.

Across the archipelago, many depots still rely on spreadsheets, WhatsApp approvals, manual reconciliation, and disconnected systems. In a business where costs change hourly and stock accuracy depends on temperature, density, and tank behavior, these methods silently extract money from every transaction.

This is why Commercial Control, not ERP digitization, is becoming the new operational standard for Indonesian fuel depot operators. This is exactly why Fuel Depot Management Indonesia is becoming a critical topic. Because in this fast-moving sector, the difference between profit and loss is often a matter of seconds and accuracy.

Factors Affecting Fuel Depot Profitability

Before we talk about losses, let’s understand what shapes depot profitability in the first place.

Here are the biggest factors affecting fuel depot profitability:

- Daily price fluctuations based on global oil markets.

- High dependency on logistics and timely delivery.

- Accurate stock measurement is affected by temperature and density.

- Contractual terms that impact freight, taxes, and discounts.

- Manual processes create inconsistencies between departments.

- Fuel quality management, which influences operational downtime and customer trust.

In Indonesia, where demand is large and supply chains stretch across islands, these factors become even more complex. Every step, procurement, storage, dispatch, invoicing, and reconciliation can either protect your margin or silently drain it.

What Actually Shapes Profitability in an Indonesian Fuel Depot

Profit is governed by far more than buying and selling fuel. Margin leakage doesn’t happen in one big event. It happens in small, repetitive errors that accumulate silently. Key drivers include:

- Global price shifts affecting landed cost.

- Freight and logistics that change per route, port, and vessel

- Temperature-density variations impacting stock accuracy

- Contract terms tied to taxes, duties, surcharges, and rebates

- Manual processes that break reconciliation integrity

- Delays in updating the supplier price or FX

Every step, procurement, storage, dispatch, invoicing, and reconciliation either protects your margin or silently drains it. This is why Fuel Depot Management Indonesia, as a discipline, demands more than “managing operations”; it demands controlling commercial decisions.

Causes of Fuel Losses in Depots

Fuel losses aren’t always malicious. Sometimes they’re simply environmental or procedural. Here are the primary causes of fuel losses in depots:

Common causes include:

- Incorrect landed cost calculations.

- Slow pricing updates that don’t keep up with supplier changes.

- Human error in manual reconciliation.

- Contract mismatches between sales and procurement.

- Freight cost inconsistencies during logistics.

- Untracked operational variances.

This is why Fuel Depot Management Indonesia, as a discipline, demands more than “managing operations”; it demands controlling commercial decisions.

Causes of Fuel Losses in Depots

Fuel losses aren’t always malicious. Sometimes they’re simply environmental or procedural. Here are the primary causes of fuel losses in depots:

- Evaporation due to temperature fluctuations.

- Density variances are not updated at the right time.

- Inaccurate tank calibration.

- Improper meter readings.

- Handling and transfer losses.

- Small leaks or uncontrolled spillage.

- Fuel inventory shrinkage due to inconsistent measurement techniques.

- Fuel measurement discrepancies across teams or tools.

But then there’s deliberate loss, pilferage, which often hides between manual processes and poorly tracked logistics movements.

Also Read: How AI-powered TMS Transforms Oil & Gas Logistics

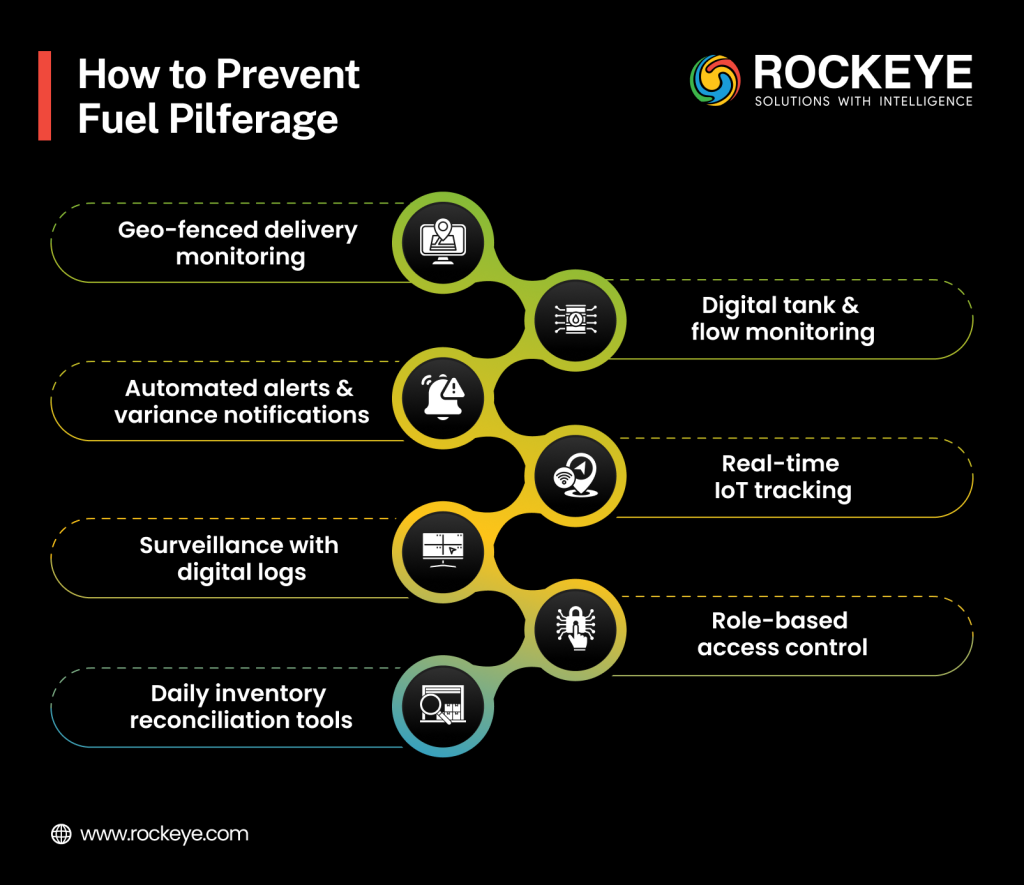

Methods to Prevent Fuel Pilferage

Pilferage is one of the biggest contributors to Fuel Depot Loss Prevention Indonesia, and manual processes only make it easier.

Effective prevention methods include:

- Digital tank and flow monitoring.

- IoT sensors for real-time tracking.

- Role-based access control to restrict manipulation.

- Geo-fenced delivery and dispatch monitoring.

- Automated exception alerts and variance notifications.

- Surveillance paired with digital transaction logs.

- Depot inventory reconciliation system tools for daily cross-checks.

With digitalization becoming the new standard, the companies leading the Indonesian downstream market are the ones proactively investing in automation, not reacting after losses occur.

Operational Risks Fuel Depots Face Without Automation

If your depot still runs on manual entries and delayed updates, these risks are unavoidable:

- Mismatch between physical vs. recorded stock.

- Delayed pricing approvals leading to accidental margin loss.

- Non-compliance with customer or supplier contracts.

- Human-driven errors across procurement, sales, and dispatch.

- No visibility into real-time margins.

- Increased pilferage opportunities.

- Untracked logistics discrepancies across islands.

- In inefficient fuel depot operations, Indonesian teams are struggling with outdated systems.

Automation isn’t a nice-to-have; it’s what separates growth-ready depots from profit-draining ones.

Why Fuel Depots Lose Money Daily: Real Scenarios from the Ground

Let’s make it real with examples that happen every day in Indonesia:

Scenario 1: A 12-hour delay in updating the supplier price

The sales team continues selling at yesterday’s rate.

By the time pricing updates are corrected, the depot has already sold at a loss.

Scenario 2: Density-temperature mismatch

Fuel measured at 28°C is reconciled as if it were 31°C.

Result: invisible stock loss and unnecessary variance reporting.

Scenario 3: Wrong freight charges applied

Logistics updates via WhatsApp don’t reach accounting.

Invoices go out with incorrect landed cost, directly affecting margins.

Scenario 4: Contract rule not updated in ERP

Customers receive a discount that shouldn’t apply this month.

Another margin leak.

These are the reasons Fuel Depot Management Indonesia requires more than ERP; it requires control.

Read Ahead: 14 Ways Vehicle Tracking Systems Save Money

Why Traditional ERPs Fail to Prevent These Losses

ERP systems are great record-keepers.

But depots don’t need record-keeping; they need real-time intelligence.

Here’s why ERPs fall short:

- They update the cost manually, not automatically.

- They can’t enforce contract rules.

- They don’t calculate real-time landed cost.

- They aren’t built for downstream fuel logistics complexity.

- They lack continuous reconciliation features.

- They function in disconnected modules that don’t reflect live margin changes.

- They aren’t designed for Fuel Depot Loss Prevention Indonesia.

You need more than a system that stores data. You need one that controls it.

Why Real-Time Commercial Control Is Essential

This is where the shift happens.

Real-Time Commercial Control for Fuel Depots means:

- Every price update reflects instantly

- Every contract, surcharge, tax, and rule applies automatically

- Every dispatch is margin-protected before release

- Every tank movement reconciles to livestock

- Every variance is flagged instantly

- Every department sees the same commercial truth

In a micro-margin business, commercial control isn’t optional; it directly determines profitability.

This is the foundation of the modern commercial control system for fuel depots.

Must Read: Downstream Supply Chain Control – Real-time Visibility in Fuel Transport

How Digital Monitoring Improves Depot Profitability

Digital monitoring transforms a depot from reactive to proactive.

Here’s how it boosts profit:

- Livestock visibility removes guesswork.

- Automated variance detection catches losses instantly.

- Real-time landed cost intelligence ensures accurate pricing.

- Digital workflow enforcement reduces human intervention.

- Fuel terminal management with dashboards gives decision-makers instant clarity.

- Fuel terminal digitalization improves audit readiness.

- Predictive alerts prevent abnormal activities.

- Digital pipelines allow smoother fuel depot logistics in Indonesia.

- Integration with a fuel depot ERP solution keeps departments aligned.

Suddenly, a depot that once fought fires daily begins to run like a predictable, controlled business.

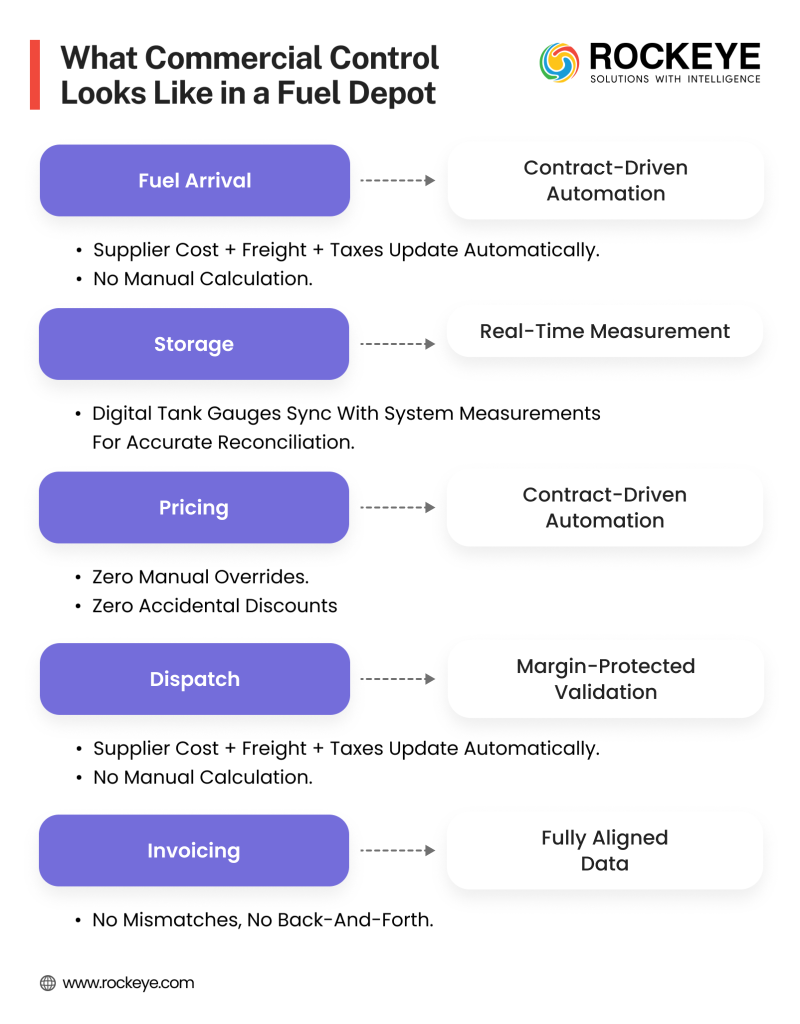

What Commercial Control Looks Like in a Fuel Depot

Here’s how an ideal commercial-control-enabled depot operates:

Fuel Arrival → Digital cost update

Supplier cost + freight + taxes update automatically.

No manual calculation.

Storage → Real-time measurement

Digital tank gauges sync with system measurements for accurate reconciliation.

Pricing → Contract-driven automation

Zero manual overrides.

Zero accidental discounts.

Dispatch → Margin-protected validation

Shipment is released only if the margin is safe.

Invoicing → Fully aligned data

No mismatches, no back-and-forth.

This is the blueprint that the best fuel terminal management system vendors follow.

Before vs After: A Depot With and Without Commercial Control

| Before | After |

|---|---|

| Spreadsheets everywhere | Real-time commercial control |

| WhatsApp-based communication | Transparent costs at every stage |

| Inaccurate reconciliation | Automated reconciliation |

| Frequent margin leaks | Protects margin per transaction |

| Delayed pricing | Digital audit trails |

| High pilferage risk | Centralized decision-making dashboards |

This is the new standard for Fuel Depot Management Indonesia, and the gap between old and new is widening quickly.

Why ROCKEYE Is the Commercial Control System Built for Indonesian Fuel Depots

ROCKEYE is not just an ERP; it’s a Commercial Control System for Fuel Depots designed specifically for downstream operations.

It offers:

- Real-time landed cost automation.

- Contract rule enforcement.

- Freight and logistics cost synchronization.

- Digital variance detection.

- IoT-enabled stock monitoring.

- Integrated depot inventory reconciliation system.

- Fuel quality management workflows.

- Fuel depot management software in Indonesia is built for local needs.

- Seamless multi-team control across procurement, sales, dispatch & finance.

For depots struggling with margin leakage, ROCKEYE is the upgrade that changes everything.

Conclusion: In Indonesia’s Fuel Market, Control = Profit

Fuel depots don’t lose money because of competition; they lose it because of missed updates, inaccurate measurements, manual errors, and disconnected systems.

The future belongs to depots that run on Real-Time Commercial Control for Fuel Depots, not manual spreadsheets.

If your business still relies on old processes, every day is another opportunity for unseen margin leakage.

Frequently Asked Questions

How can automation reduce depot shrinkage?

Automation reduces fuel inventory shrinkage by tracking fuel movements in real time, detecting anomalies, and reconciling stock automatically. Sensors, IoT devices, and digital workflows ensure every liter is accounted for, minimizing evaporation, handling errors, and pilferage.

How can I prevent depot operational losses?

Preventing depot operational losses starts with real-time commercial control and automation. Key steps include:

- Implementing a fuel inventory control system in Indonesia.

- Automating tank monitoring and stock reconciliation.

- Applying contract rules automatically.

- Monitoring KPIs like margin per transaction, dispatch accuracy, and stock variance.

Together, these measures minimize human error, shrinkage, and financial leakage.

How do I track depot commercial KPIs?

Tracking KPIs in fuel depot operations in Indonesia is easier with real-time depot automation solutions. Dashboards and analytics provide instant visibility into:

- Margin per product

- Stock variance and shrinkage

- Delivery and dispatch accuracy

- Contract compliance

This allows managers to take immediate corrective action and protect profitability.

How does a Sistem Kontrol Komersial Depot BBM protect margins?

A sistem kontrol komersial depot BBM ensures that all pricing, contracts, and transactions are applied accurately and automatically. This prevents fuel depot margin losses caused by manual errors, incorrect cost calculations, or contract mismatches.

How can I improve fuel depot operations in Indonesia?

Improving fuel depot operations in Indonesia starts with centralizing control over your inventory, pricing, and logistics. Implementing a fuel inventory control system in Indonesia ensures every liter is tracked in real-time, reducing errors and preventing margin loss. Combined with fuel terminal automation vendors in Indonesia, you can automate tank monitoring, dispatch, and reconciliation, making your depot operations more efficient, transparent, and profitable.

What solutions prevent fuel depot losses in Indonesia?

To prevent losses, depots need a combination of real-time monitoring, automation, and process control. A fuel depot loss prevention Indonesia strategy includes digital stock reconciliation, IoT-based tank monitoring, automated reporting, and integrated logistics tracking. This ensures you minimize fuel inventory shrinkage, reduce human error, and maintain accurate margin control.

How can fuel depot logistics in Indonesia be optimized?

Optimizing fuel depot logistics in Indonesia requires live visibility into dispatch, delivery routes, and inventory. Using fuel terminal automation vendors’ Indonesia solutions allows depots to synchronize logistics with stock levels and contract requirements. Automated workflows reduce delays, improve delivery accuracy, and protect margins, ensuring that operations run smoothly even across multiple terminals or islands.

Why is a fuel inventory control system important for depots in Indonesia?

A fuel inventory control system in Indonesia provides real-time visibility into stock levels, usage patterns, and losses. This system helps detect discrepancies quickly, supports fuel depot loss prevention in Indonesia, and enables better decision-making for procurement and dispatch. Integrating such a system with automated terminals ensures that every transaction is accurate, reducing errors and safeguarding depot profitability.