In downstream logistics, the gap between what’s happening on the ground and what leaders think is happening remains the biggest source of revenue leakage. Most terminal operators rely on fragmented legacy systems, making it impossible to enforce a unified Commercial Control System across loading racks, tank farms, transport fleets, and depot operations.

This is exactly where a Downstream Commercial Revenue OS becomes transformative, by creating a real-time, validated, tamper-proof view of fuel movement from tank to truck to customer.

With solutions like the ROCKEYE Fluid Terminal Management module, operators consistently report an 18% reduction in fuel losses and 30% improvement in dispatch efficiency. These aren’t theoretical benchmarks; they’re the outcome of eliminating blind spots, enforcing movement authentication, and providing commercial and operations teams with a single source of truth.

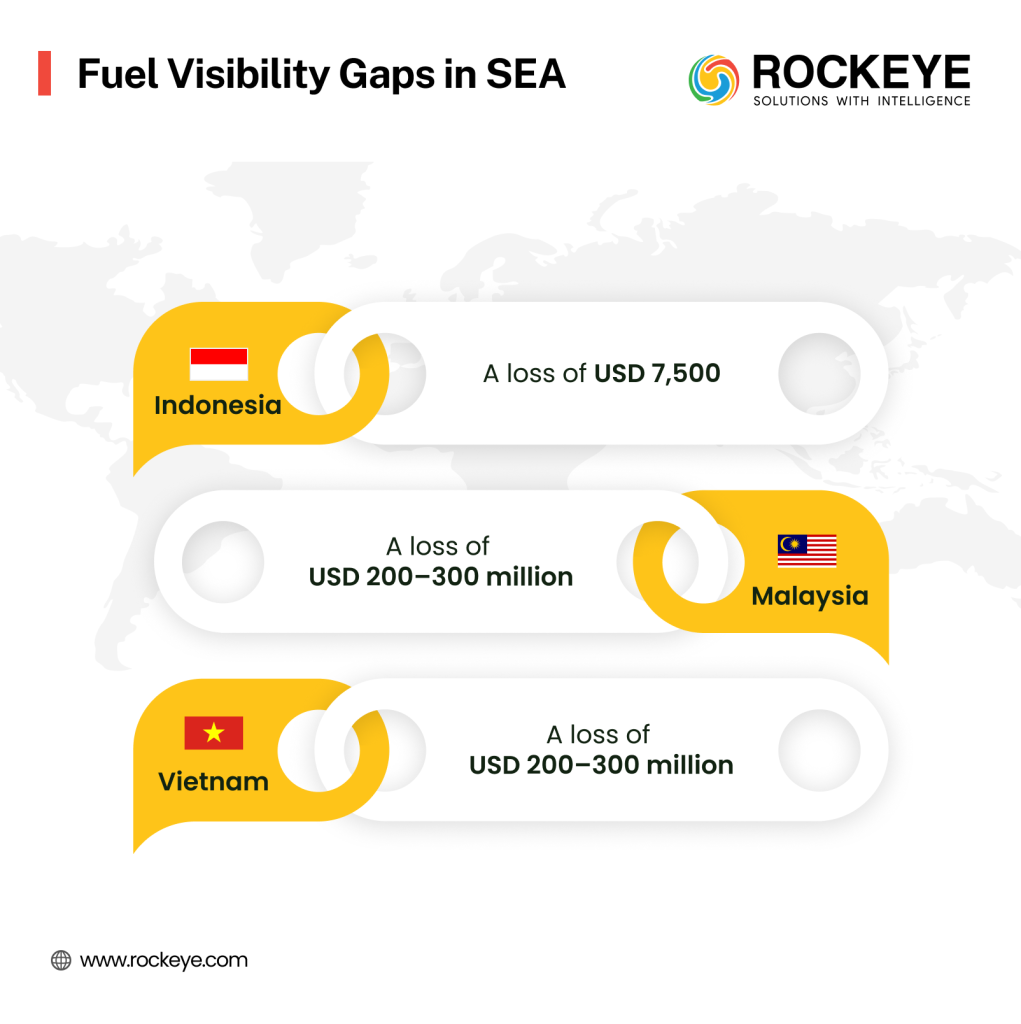

The Impact of Fuel Visibility Gaps in Southeast Asia

Across Southeast Asia, most downstream operators face a recurring problem: fragmented visibility across terminal, transport, and depot movements. While the scale differs across Indonesia, Malaysia, and Vietnam, the operational pain points are the same: slow truck turnarounds, stock variance, reconciliation delays, and dispatch misalignment. These gaps directly impact margins, compliance, and customer commitments.

Indonesia: Multi-Node Distribution → High Reconciliation Burden

Indonesia’s fuel supply chain stretches across thousands of islands, making it a prime target for diversions, siphoning, and fraud. Wide inter-island distribution and thousands of small depots mean fuel often moves through multiple hand-offs without a unified system of record.

- Average truck TAT at smaller island terminals still ranges 2.8–3.4 hours (vs. ~1.1 hours in Singapore benchmarks).

- Monthly reconciliation variance commonly sits around 0.6–1.1% due to manual logs and inconsistent ATG data.

- 18–25% of loads require manual rework because digital BOLs or weight-bridge data fail to sync.

Operational Cost Impact: Idle queues, variance adjustments, and emergency top-ups cost operators an estimated IDR 85–140 million per 50-truck fleet monthly, all driven by visibility gaps.

Malaysia: Stringent Terminal Compliance → Need for Clean Audit Trails

Malaysia’s terminals may be among the most tightly regulated in the region, but compliance without visibility often results in more paperwork than progress. Strict DOSH/DOE compliance requires complete movement traceability; however, many terminals still operate using Excel and paper-based sequencing.

- Shift supervisors spend 4–6 hours/day reconciling truck-to-tank movements instead of <30 minutes with automation.

- 5–7% of terminal operating cost comes from reconciliation errors, untraceable gains/losses, or rework for audit fixes.

- Audit certification delays stretch 7–14 days per quarter due to incomplete trails.

Commercial Impact: Medium-sized terminals absorb RM 1.2–2.1 million/year in extra manpower, overtime, and audit-related costs.

Vietnam: Multi-Vendor Fleets → Inconsistent Transport Monitoring

Vietnam’s diversified vendor ecosystem is both a strength and a weakness. Multiple carriers mean agility, but also inconsistent tracking, patchy GPS adoption, and planning blind spots. With 70% of fuel moved by 3PL transporters, visibility is inconsistent across fleets.

- Only 38–42% of contracted trucks provide reliable GPS/temperature data.

- Dispatch queues face 2.1-hour average delays due to no-shows or wrong-compartment vehicles.

- Fuel usage per trip is 12–18% higher for fleets lacking telematics optimisation.

- Depot stock variance sits at 0.7–1.0% monthly.

Financial Impact: Multi-vendor fleets with 120+ trucks lose VND 9–15 billion/year to idling, rerouting, and manual reconciliation efforts.

Also read: How AI-powered TMS Transforms Oil & Gas Logistics

Real-time Visibility Cuts Fuel Loss, Idle Time & Dispatch Delays

Real-time data only matters when it creates commercial control, and in Southeast Asia’s fragmented downstream supply chains, that control directly translates into measurable impact. When terminals, gantries, gates, and fleets operate on live signals, operators eliminate the blind spots that quietly erode margins every day. Customers running the ROCKEYE Fluid Terminal Management module inside the Downstream Commercial Revenue OS consistently report an 18% reduction in fuel loss through continuous reconciliation and anomaly detection, and 30% faster dispatch cycles from AI-led scheduling and automated gate orchestration. This is the difference between reacting late and controlling the operation as it happens.

Take the example of a large downstream operator like MRS Holdings in West Africa. By moving to a unified control layer with automated loading, digital BoL, and continuous tank-to-fleet reconciliation, they transformed multi-terminal operations,removing manual rework, compressing planning time, and turning bottlenecks into throughput gain. Their experience demonstrates the same principle SEA operators seek: when every litre, vehicle, and terminal event is live, predictable, and validated, commercial performance moves sharply upward.

What Real-Time Visibility Really Means for Downstream Control

Real-time visibility isn’t about “tracking trucks.”

It’s about building a live commercial control spine from

tank farm → gantry → gate → fleet.

The ROCKEYE Fluid Terminal Management module connects ATGs, flow meters, temperature sensors, density monitors, GPS, valve states, and gantry events into one continuous stream. It eliminates leak uncertainty, flags abnormal movement instantly, and keeps system stock aligned with physical stock—driving leak reduction as a daily outcome, not a quarterly clean-up.

On the road, operators get route validation, geo-fence alerts, auto trip creation, and compartment-level correctness checks, tightening margins by preventing wrong product loading, unnecessary idling, and emergency procurement caused by dispatch misalignment.

Inside terminals, automated loading racks, real-time tank-farm visibility, and digital gate-in/gate-out orchestration drive throughput uplift, ensuring trucks don’t queue blindly and dispatchers don’t plan with stale data.

Everything flows into a unified SCADA → MES → ERP integration layer inside the Downstream Commercial Revenue OS, creating the single source of truth that operations, finance, and compliance teams can finally trust.

The outcome?

A downstream operation where anomalies are caught instantly, reconciliation becomes continuous, dispatch moves 30% faster, fuel loss drops by 18%, and compliance teams receive complete, auto-generated movement trails without chasing paper.

Consequences of Not Having Real-time Visibility

When a terminal or fleet runs without real-time control, blind spots don’t just create confusion, they erode margins, throughput, and fuel integrity every single day. Here’s how fast the impact escalates when the control layer is missing:

Risk without control: Truck idling at a gantry for 3 hours

Impact: Lost throughput + idle burn → higher operational cost per trip

Risk without control: No live stock sync between depot and terminal

Impact: Variances accumulate → emergency procurement spikes margins by 8–12%

Risk without control: Route deviations or non-optimized journeys

Impact: Extra distance + extra fuel → inflated cost per delivered litre

Risk without control: Delayed detection of leaks or unauthorized withdrawals

Impact: Unaccounted loss increases → directly hits the 18% leak-reduction target

These failures happen because spreadsheets, manual logs, and delayed entries cannot maintain the commercial discipline required in high-volume downstream operations.

The ROCKEYE Fluid Terminal Management module, inside the Downstream Commercial Revenue OS, closes these gaps by creating a live commercial control layer that spans:

- Continuous tank reconciliation → cuts leak uncertainty

- Automated gantry validation → eliminates wrong loading & reduces variance

- Real-time gate & route orchestration → uplifts dispatch throughput by 30%

- Digital BoL + full movement traceability → strengthens audit compliance

Real-time control transforms downstream logistics from reactive firefighting to predictable, margin-protective operations where every litre, truck, and terminal event is accounted for the moment it happens.

Also read: 7 Essential Features of Modern Terminal Management Systems in Oil and Gas

Why Downstream Control Breaks Without Real-Time Visibility

Downstream fuel logistics is the most fragmented stage of the oil & gas value chain, with multiple terminals, hundreds of vehicle movements, and strict safety and tax compliance. Once fuel leaves the refinery gate, every minute, every kilometre, and every litre becomes a variable that must be controlled in real time.

But most operators still rely on Excel sheets, siloed terminal systems, and manual dispatching, making coordinated control nearly impossible.

Here’s what real “downstream control” actually means in practice:

| Control Dimension | What It Means | Real Example |

|---|---|---|

| Inventory Control | Know exactly where fuel is, in what quantity, at all times. | 98.7% stock accuracy at terminal. |

| Transport Control | Track every truck, route, and event in real time. | GPS shows the truck is 12 minutes from the depot. |

| Dispatch Control | Auto-assign loads and optimize schedules instantly. | 47 loads scheduled in 3 minutes. |

| Cost Control | Reduce idle time, detours, demurrage & fuel burn. | 2.1 hours idle time saved per truck/day. |

| Compliance Control | Keep audit-ready records without manual effort. | Auto-generated HAZMAT & tax documents. |

These are not possible in slow, offline, or paper-based systems.

They require connected terminals, integrated fleet visibility, automated dispatching, and a unified control layer, exactly what modern platforms like ROCKEYE’s Fluid Terminal Management module deliver.

How ROCKEYE ERPs’ Fluid Terminal Management Enables End-to-end Control

ROCKEYE isn’t a typical ERP module bolted onto operations. It is a Downstream Commercial Revenue Operating System engineered around three core levers that determine profitability in fuel logistics:

1) Leak Reduction

2) Margin Tightening

3) Throughput Uplift

Every workflow, from loading to dispatch to delivery, is designed to eliminate waste, protect revenue at the source, and maximize the speed and efficiency of terminal operations. Because the system adapts to your operational reality, ROCKEYE becomes the control layer, not a tool you adjust your process for.

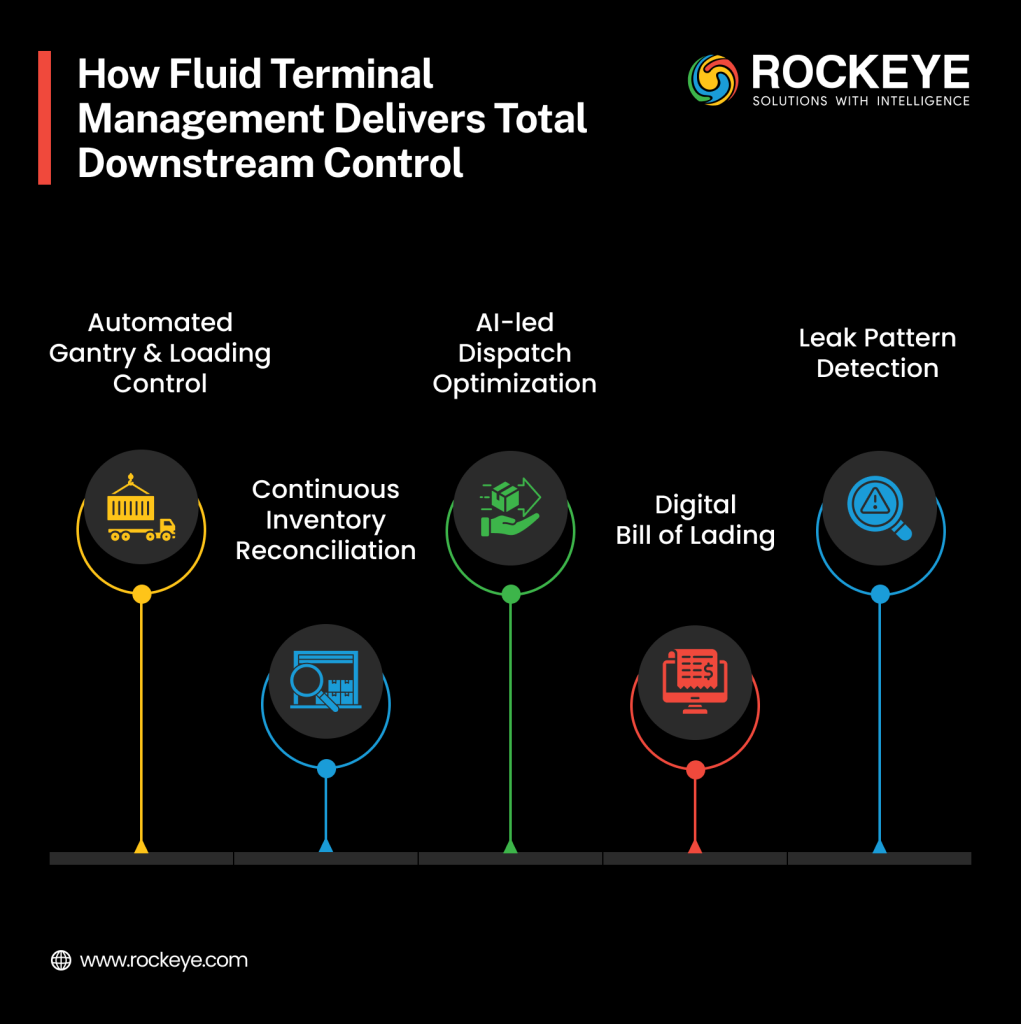

Automated Gantry & Loading Control (Leak Reduction + Margin Tightening + Throughput Uplift)

ROCKEYE’s automated gantry management validates trucks, drivers, compartments, orders, density, and product type before a single litre moves.

- Manual overrides, misloads, and undocumented top-ups are eliminated thanks to system-controlled sequencing and flow-meter validation.

- Correct product + correct density + correct cost are enforced at source, preventing costly re-deliveries and emergency procurement.

- Pre-validated loads reduce gantry dwell time and accelerate gate-in/gate-out cycles.

The result is predictable, auditable, margin-protected loading with near-zero variance.

Continuous Inventory Reconciliation (Leak Reduction + Margin Tightening)

ROCKEYE syncs ATG readings, valve states, and flow meter data every few seconds, creating a real-time commercial record across all tanks.

- Instant detection of “ghost losses,” slow leaks, and unaccounted draw-offs.

- Inventory accuracy ensures correct cost-of-goods, eliminates backdated corrections, and supports defensible audits.

Regulatory compliance becomes automatic, not an afterthought.

AI-led Dispatch Optimization (Throughput Uplift + Margin Tightening)

ROCKEYE’s dispatch engine evaluates traffic patterns, driver HOS, customer SLAs, gantry queues, product availability, and load constraints to auto-generate the optimal plan.

- 30% faster dispatch cycles, reduced waiting, and higher fleet utilization.

- Lower per-trip cost through fewer detours, minimized idle time, and optimal route sequencing.

This isn’t scheduling, it’s throughput maximization with commercial intent.

Digital Bill of Lading (Leak Reduction + Margin Tightening)

Every loading, transit, and delivery event is captured via secure mobile workflows.

- Eliminates paperwork errors, fraudulent edits, and POD manipulation.

- Delivery data flows instantly into billing, eliminating disputes and accelerating revenue recognition.

Audit trails become fully digital, consistent, and regulator-ready.

Theft & Leak Pattern Detection (Leak Reduction)

ROCKEYE continuously analyzes:

- pressure variations

- unexpected volume drops

- abnormal flow signatures

- route deviations

Any anomaly triggers a real-time alert to control teams. Field response time drops from hours to minutes, preventing large-scale siphoning and high-risk route losses.

This single feature alone protects millions in annual fuel shrinkage for large operators.

Conclusion

Real-time visibility is no longer an operational upgrade; it’s the backbone of downstream commercial control. As Southeast Asian fuel networks grow more complex and risk-prone, leaders need terminal management software that protects margins, tightens compliance, and eliminates leakage at every stage. With the right platform, fuel logistics becomes predictable, accountable, and commercially efficient.

FAQs

Here are quick answers to the most common questions fuel logistics leaders ask about real-time visibility and downstream control.

1. What does real-time visibility mean in fuel transport?

Real-time visibility refers to the ability of a Downstream Commercial Control System like ROCKEYE, with its Fluid Terminal Management module, to track inventory, loading activity, fleet movement, and delivery events the moment they occur. Operators get instant alerts, enabling proactive action instead of reactive firefighting.

2. How does real-time visibility reduce fuel loss?

ROCKEYE continuously monitors tank levels, flow patterns, route adherence, and density changes. Any anomaly, whether a sudden volume drop, mid-route diversion, or compartment mismatch, is flagged instantly. This immediate detection prevents unnoticed leakage, misloads, and theft.

3. Why is downstream control especially critical in SEA markets?

Southeast Asia’s multi-terminal, inter-island, and multi-vendor environment introduces higher exposure to loss, delay, and compliance risk. A control system like ROCKEYE provides live traceability across vessel arrivals, gantry queues, island-hopping fleets, and depot stock levels, making operations predictable and audit-secure.

4. Can ROCKEYE integrate with existing terminal or transport hardware?

Yes. ROCKEYE is designed to unify operational data by integrating directly with ATGs, flow meters, SCADA systems, GPS devices, RFID gantry controls, and driver mobile apps, creating a single source of truth for operations, finance, and compliance.

5. What commercial benefits can operators expect from a system like ROCKEYE?

ROCKEYE delivers measurable impact across the value chain:

- lower operational leakage

- Reduced emergency procurement

- faster dispatch and turnaround cycles

- tighter margin protection at loading and delivery

- audit-ready documentation across terminals and fleets

It becomes the commercial nerve center of downstream operations.