If you’ve ever had to manage the chaos of inventory imbalances, delayed procurements, or warehouses operating at maximum capacity, you already know that guesswork is no longer sustainable. The future of sound material movement lies in the fusion of AI and ERP. This powerful combination transforms static data into living intelligence that predicts, plans, and perfects your supply flow. AI for inventory management is not just the future but the present as well.

Recent studies show that AI-integrated ERP systems reduce stockouts by up to 50%, cut excess inventory by 20–35%, and boost forecast accuracy by 15–30%. By 2026, inventory management won’t just be about storage and movement; it’ll be about smart anticipation, where every material decision is driven by precision and foresight. Do you want to know how AI inventory optimization works? And how will it prove to be a game-changer in predicting the volatility in the next year? Consider this blog worth reading.

Also read: How Can the Right Warehouse Inventory Management Software Cut 40% of Operational Costs?

Understanding the Power of ERP Data in Inventory Forecasting

If data is the new oil, then ERP systems are the refineries powering your entire supply chain engine. Every purchase order placed, every sale closed, every shipment delayed, it all flows through your ERP system, silently collecting insights from procurement, sales, supplier performance, and logistics.

This interconnected web of data forms the backbone of accurate stock prediction. Sales velocity highlights how quickly products move through your system, while lead time variability signals potential bottlenecks. Supplier reliability metrics uncover patterns of consistency or delay, and production schedules and demand forecasts reveal what’s coming next.

No wonder the global AI in ERP market is projected to surge from USD 5.8 billion in 2025 to USD 18.7 billion by 2030 (CAGR 26.4%). When ERP data meets AI, businesses unlock precision-driven decisions that optimize procurement timing, safety stock, and reorder points, long before shortages strike. Artificial intelligence in inventory management is key to managing the growing demand for production.

How AI Converts ERP Data into Accurate Stock Predictions

ERP systems hold the data, but AI gives it the intelligence to act. By combining machine learning, advanced analytics, automation tools, and predictive algorithms, ERP platforms evolve from passive data repositories into proactive engines that optimize decision-making end to end. This fusion enables businesses to move beyond static reporting toward dynamic forecasting that anticipates demand shifts, procurement delays, supplier risks, and inventory fluctuations. machine learning.

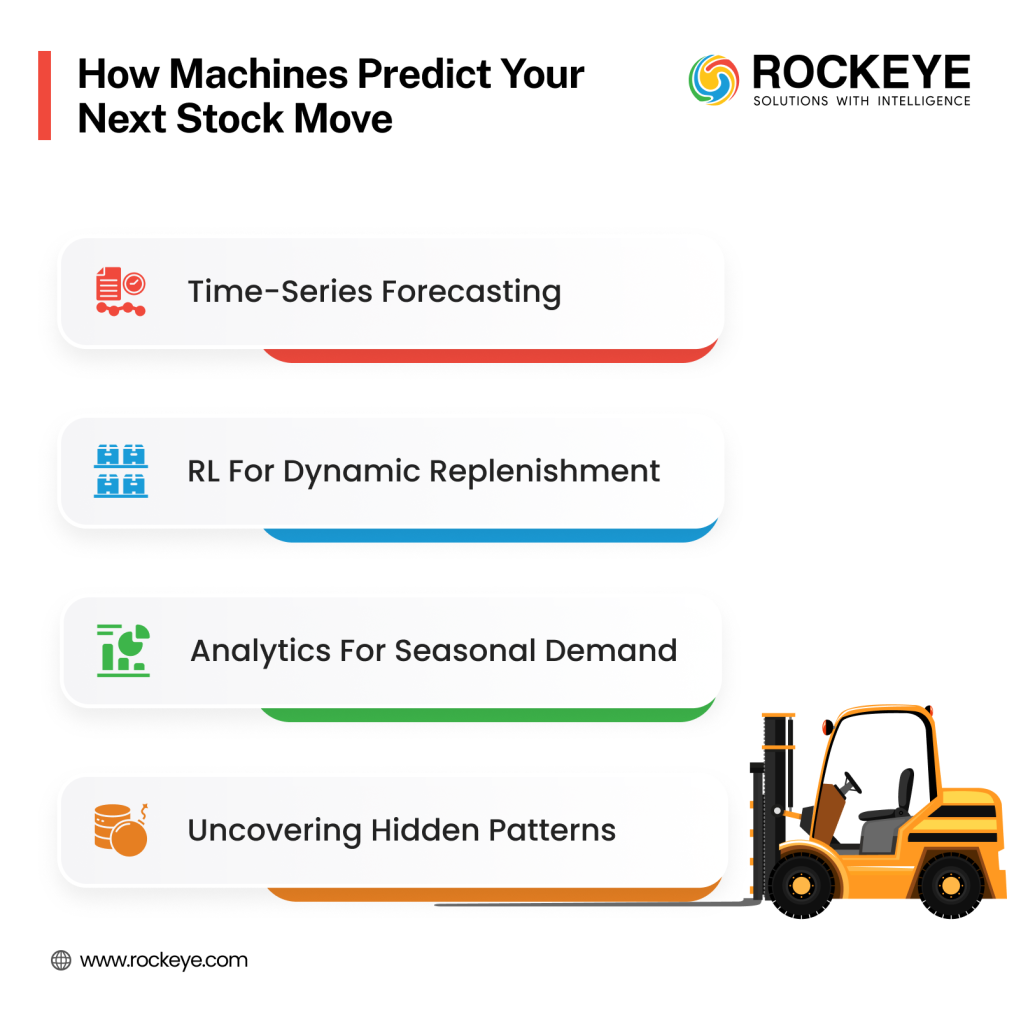

Time-series Forecasting

- Analyzes historical inventory and sales data to predict future demand patterns.

- Adapts to fluctuations like seasonal peaks, product launches, or regional trends.

- Enables planners to anticipate stock requirements weeks, even months in advance.

Reinforcement Learning for Dynamic Replenishment

- Continuously learns from outcomes to make smarter restocking decisions.

- Balances inventory levels, cost efficiency, and service quality in real time.

- Automatically recalibrates reorder thresholds based on changing conditions.

Predictive Analytics for Seasonal Demand

- Combines weather data, promotions, and market signals to forecast seasonal shifts.

- Helps businesses stock the right materials at the right time, reducing waste and shortages.

Uncovering Hidden Patterns and Trends

AI digs deeper than spreadsheets ever could. It identifies subtle correlations across sales, supplier reliability, and material usage. It spots:

- Sudden spikes in consumption could signal rising demand.

- Procurement delays before they disrupt production.

- Abnormal usage patterns indicate inefficiencies or shrinkage.

Key Features of an AI-powered Inventory & Warehouse Management Solution

AI-powered inventory and warehouse systems are transforming traditional stockrooms into intelligent ecosystems. They blend automation, analytics, and real-time visibility to eliminate inefficiencies, minimize manual errors, and enable data-backed decision-making.

By combining ERP data with predictive AI, businesses gain full control over inventory dynamics, from inbound materials to outbound logistics. Here’s how:

Stock Management

Achieve agile inventory control through real-time monitoring and precise movement tracking, ensuring optimal stock levels across all locations.

Ownership Management

Efficiently manage items with distinct ownership structures, offering complete visibility into stock distribution and accountability.

Batch Management

Implement systematic barcoding and tagging to enhance accuracy, traceability, and regulatory compliance in your inventory systems.

Tradable & Non-tradable Tracking

Maintain transparency by distinctly tracking tradable and non-tradable items, ensuring precision in valuation and movement.

Advanced Reporting

Gain actionable insights through advanced analytics, including stock summaries, batch details, and bin availability reports.

Label Printing & Scanning

Boost efficiency with barcode scanning and label printing, allowing continuous, error-free tracking across the warehouse floor.

Order Completion

Streamline fulfillment by processing multiple orders simultaneously, ensuring packaging accuracy and on-time delivery.

Delivery & Logistics

Oversee the entire delivery cycle, from pickup to customer confirmation, with AI optimizing routes, costs, and turnaround time.

Also read: 5 Key Benefits of Inventory Visibility For Smarter Warehousing And Fulfillment

Real-world Use Cases of AI-powered ERP Forecasting

The power of AI-driven ERP forecasting isn’t theoretical. AI in inventory management is already redefining how global enterprises manage supply, demand, and procurement.

By layering advanced AI models over ERP systems, leading companies are achieving remarkable gains in efficiency, accuracy, and cost savings. Here’s a look at how top brands are putting AI-powered forecasting into action:

| Company | ERP System | AI Layer / Platform | Use Case & Outcomes |

|---|---|---|---|

| Walmart | Oracle Cloud ERP | Oracle Autonomous Supply Chain + ML Demand Sensing |

Predicts 2.2 B+ item–store combinations daily. → 40% ↓ stockouts → 25% ↑ forecast accuracy → $1.2B saved in inventory carrying costs. |

| Heineken | SAP S/4HANA | Blue Yonder Luminate Cognitive Platform |

AI-based demand sensing across 70+ countries. → 32% ↓ excess inventory → 18% ↑ service levels → €85M working capital freed. |

| Hidden Brains | ROCKEYE ERP | ROCKEYE AI/ERP Inventory Module |

Unified operations from yarn to shipment. → 95% inventory accuracy → 30% faster production cycles → 25% reduction in rework/waste → 40% improvement in on-time delivery rate |

| Siemens | SAP S/4HANA Cloud | SAP Leonardo AI + Predictive Analytics |

Forecasts 1.2M+ spare parts globally. → 28% ↑ forecast accuracy → 45% ↓ emergency orders → €120M inventory reduction. |

| Unilever | SAP S/4HANA + Anaplan | Anaplan AI + Connected Planning |

400+ brands spanning 190 countries. → 22% ↓ overstock → 15% ↑ forecast accuracy → £90M cash-flow improvement. |

Benefits of AI in Inventory Management

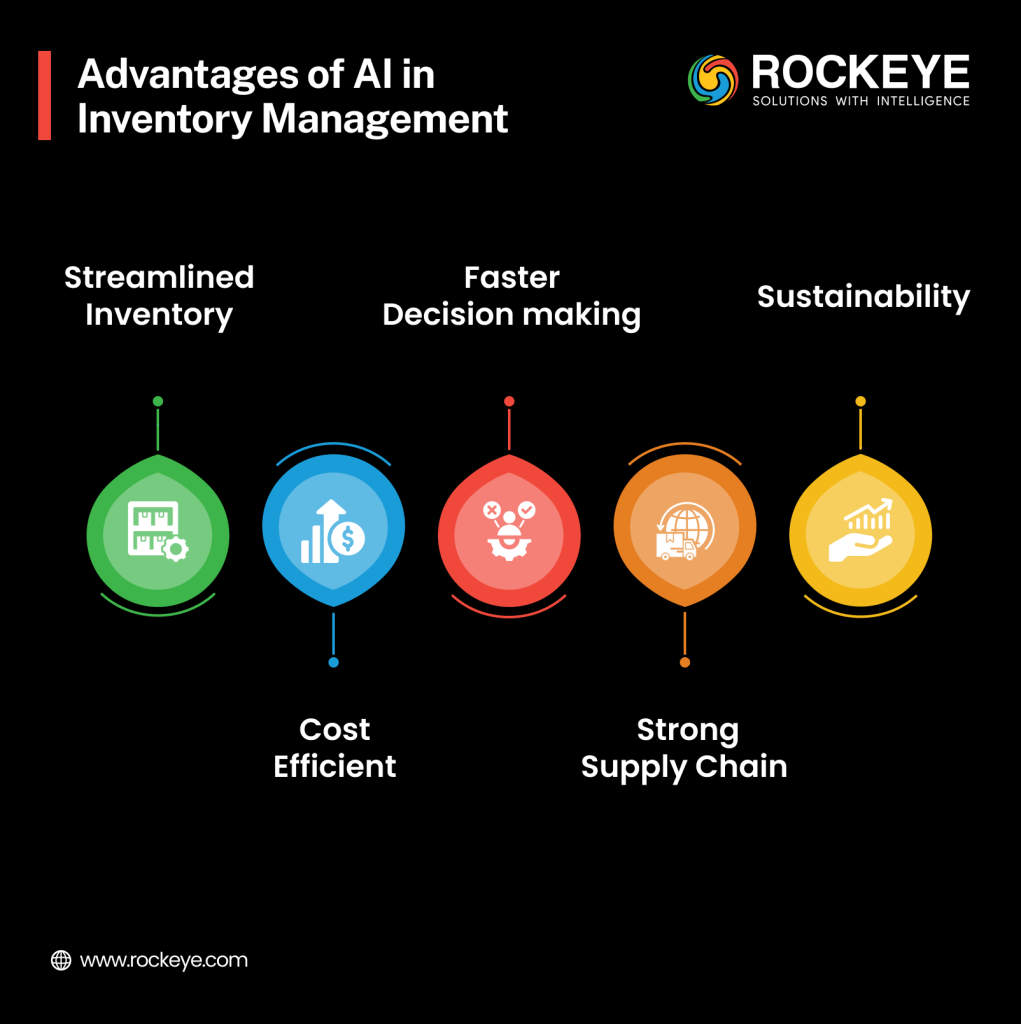

Inventory management is transformed into an intelligent, proactive system powered by AI and constantly learns and adjusts to changes, thereby making stock predictions. This is how it can benefit you:

- Streamlined Inventory: Prevents overstocking or stockouts by using accurate, data-driven demand forecasting.

- Economy: Minimizes carrying costs and waste in the procurement process by aligning procurement with actual needs.

- Faster Decision-making: Predictively automates re-order operations and saves on direct supervision.

- Strong Supply Chain: It anticipates disruptive events and dynamically restructures procurement approaches to sustain flow.

- Sustainability: Less material wastage caused by smarter planning and environmentally friendly operations. This combination of advantages makes AI not only a technological upgrade but a competitive advantage for supply-based companies.

Future Outlook: What 2026 Holds for Smart Warehousing and Procurement

- AI & Robotics: AMRs and AI-controlled robots will be used to pick, route, and move products with precision.

- IoT-based visibility: It will facilitate predictive maintenance and smooth workflows, enabled by real-time data analytics.

- Integration of Cloud + ERP: Cloud-based WfMS from WfMC will integrate with ERP to ensure real-time decision-making.

- Market Growth: The smart warehousing market will expand at a CAGR of more than 8 percent due to e-commerce and automation.

- Sustainability Focus: The concept of green logistics will be transformed through solar energy, eco-efficient systems, and smart energy management.

The 2026 warehouse will not only operate but also think.

How ROCKEYE ERP Can Be a Game-Changer?

Are you willing to change your inventory operations? ROCKEYE ERP inventory management module is here. The system will provide complete visibility, real-time analytics, and inventory, warehouse, and procurement processes. Streamline stock levels, reduce expenses, increase precision, and transform complicated supply chains into strategic benefits. Transform your warehouse game today!

Conclusion

With AI transforming ERP systems, companies adopting intelligent forecasting will be able to stay ahead of disruptions and competition. It is data-intensive precision and proactive decision-making that will help manage stocks in the future. Enterprises can turn challenges into opportunities by adopting AI for inventory management and building smarter, faster, and more sustainable supply chains.

FAQs

With AI changing the way companies manage inventory and procurement, the question of how it is applied in practice and how it works in real-life scenarios is a topic of numerous inquiries. This is how AI-based inventory management works:

1. How is AI used in inventory management?

The smarter, more responsive inventory is achieved by AI reviewing ERP cash flow data and real-time warehouse data to predict demand, automate restocking, and prevent overstock or shortages.

2. Does AI enhance procurement accuracy?

Yes. AI rates suppliers’ performance, lead times, and records to recommend the most suitable time and vendor for purchase orders.

3. Which kinds of businesses are the best beneficiaries of AI-based ERP systems?

The most affected sectors are manufacturing, retail, logistics, and e-commerce, where many companies have intricate supply chains and unpredictable demand.

4. Does AI warehouse fully automate?

Not completely. AI does not replace human labor. Robots and algorithms can be used when routine tasks are performed, with humans responsible for supervising and making decisions.

5. What is the speed at which businesses can realize the results after implementation?

Normally, in a couple of months. The use of AI to enhance forecast accuracy, optimize costs, and simplify procurement delivers nearly instant results upon integration.