In a global logistics landscape shaped by volatile trade flows, rising volumes, and demand for speed, ports and terminals across Southeast Asia and Africa face mounting pressure. For leaders in Indonesia, Vietnam, Malaysia, as well as East African hubs such as Kenya, delays or inefficiencies at terminals can quickly erode margins, jeopardise client relationships, and impact competitiveness.

This makes adopting an AI‑powered terminal management system (TMS) or a full Downstream Commercial Control System (DCCS) not just a technology upgrade, but a strategic imperative.

Below, we explore how such AI‑powered terminal & throughput management adapted to regional ports can slash downtime by 30–50%, raise throughput, and future‑proof operations.

Regional Port & Terminal Trends: Why the Pressure Is Real

Port Growth & Throughput Expansion

- In Kenya, the Port of Mombasa, the region’s main gateway, handled 41.1 million tonnes of cargo in 2024, up from 35.98 million tonnes in 2023, a growth of ~14%.

- Container traffic at Mombasa in 2024 surpassed 2 million TEUs for the first time in over a decade, 2,005,076 TEUs, a jump of 23.5% year‑on‑year.

- In Vietnam, the container port throughput was reported at ~20.78 million TEU in 2023, reflecting robust growth in containerised trade.

- Meanwhile, ports like Hai Phong Port in northern Vietnam reported nearly 40 million tonnes of throughput in 2024, along with record revenues and profits underlining demand for capacity and efficiency.

These numbers confirm that ports in these regions are under real pressure: containerised cargo, bulk shipments, transit freight, and regional trade flows are all rapidly rising. Without improved terminal & throughput management, growth brings risk: congestion, delays, breakdowns, and inefficiencies.

Capacity, Infrastructure & Operational Challenges

As volume rises, many ports in Southeast Asia and Africa still operate with legacy terminal management practices. Key challenges:

- Sub‑optimal scheduling of vessel berths, yard allocation, gate operations, and container stacking → leading to idle time, congestion, and slower turnaround.

- Maintenance of heavy equipment (cranes, gantry cranes, yard vehicles, conveyors) remains largely reactive. Unexpected breakdowns cause long stoppages and cascading delays.

- Lack of real‑time visibility and analytics means bottlenecks, resource under-utilisation, or safety risks often remain undetected until it’s too late.

This gap between rising demand and limited operational agility is exactly what makes AI‑powered terminal management systems so valuable.

How AI‑Powered Terminal & Throughput Management Makes a Difference in These Regions

1. Predictive Maintenance & Asset Reliability at Scale

By integrating IoT sensors on equipment cranes, yard vehicles, conveyors, and gate machinery, a modern terminal management system can feed data into AI/ML engines that detect early signs of wear, anomalies, or potential failures (vibration, temperature spikes, unusual stress patterns).

This enables proactive maintenance instead of reactive equipment that is serviced at optimal times (e.g., low traffic windows), reducing unplanned downtime and avoiding major breakdowns. Over time, this improves asset lifespan and reliability.

Especially in high‑traffic ports like Mombasa or Hai Phong (with growing load), this translates to fewer stoppages, smoother operations, and consistent throughput even as demand scales.

2. Real-Time Visibility, Smart Scheduling & Resource Optimization

AI-powered TMS goes beyond maintenance: it becomes the central nerve‑centre for terminal operations. It enables:

- Dynamic berth scheduling & crane/yard/gate resource allocation based on real‑time data (incoming vessels, container queues, yard capacity, truck/gate traffic).

- Yard & container stacking optimisation to minimise re‑handles, reduce idle yard space, and speed up loading/unloading operations.

- Real‑time visibility dashboards, decision-makers at the C‑suite or operations level get live insights: equipment health, throughput metrics, gate/truck queue status, vessel ETAs.

For fast‑growing ports in Southeast Asia and Africa, this coordination dramatically reduces idle times, avoids bottlenecks, and ensures smoother container flow even during traffic surges.

3. Throughput Maximization with Smart Planning & AI‑Powered Logistics Flow

With the right data (equipment status, yard usage, vessel arrival predictions, gate and truck traffic), AI systems or even “digital‑twin” models can simulate entire terminal operations, foresee stress points, and optimize container flow end‑to‑end.

This means: faster vessel turnarounds, higher container unloading/loading rates, smoother transitions from ship to yard to gate/truck, and ultimately, higher throughput with fewer disruptions.

In fast‑growing container economies like Vietnam, Indonesia, or transit‑heavy ports in Kenya, this kind of throughput uplift isn’t a “nice‑to‑have”; it’s critical to meet demand, maintain reliability, and stay competitive.

Also Read: 7 Essential Features of Modern Terminal Management Systems in Oil & Gas

Why AI‑Powered Terminal Management Is a Strategic Advantage for Southeast Asia & Africa — Not Just a Technology Upgrade

For decision‑makers (CEO, CFO, CTO) in ports, terminals, or logistics operations across Malaysia, Indonesia, Vietnam, and Kenya. Here’s why investing in an AI‑powered TMS / DCCS makes strong business sense:

| Strategic Benefit | Regional Relevance |

| Scalable throughput without linear cost growth | As container and cargo volumes surge (e.g. +14% at Mombasa, strong growth in Vietnamese ports), AI enables handling growth without proportionally scaling manpower or risking breakdowns. |

| Better asset utilisation & lower CapEx/OpEx | Predictive maintenance extends equipment life, reduces repair costs. Avoiding downtime preserves revenue during peak traffic. |

| Improved reliability & operational reputation | Faster turnaround, fewer delays, and consistent throughput help attract more shipping lines , especially important for ports positioning as regional hubs (East Africa, Southeast Asia). |

| Agility in volatile global trade conditions | Global events (shipping disruptions, rerouting, demand surges) often hit ports hard. AI‑powered operations provide responsive scheduling, predictive planning, and buffer capacity. |

| Compliance, governance & safety | With sensor data and analytics, terminals can monitor equipment health, environmental factors, and safety metrics, helping meet regulatory, environmental, and stakeholder expectations. |

In short: for ports and terminals in these fast‑growing, high‑demand regions, AI‑powered terminal management isn’t optional; it becomes a core enabler of growth, profitability, and operational stability.

What It Takes to Realise the Benefits (Regional Implementation Considerations)

Of course, deploying AI-powered terminal management across Southeast Asia or Africa involves more than installing software. Key prerequisites:

- Sensor and IoT infrastructure — cranes, yard vehicles, conveyors, gate systems need sensors to collect real-time data.

- Integration across systems — terminal operating system (TOS), maintenance logs, vessel data, yard & gate operations, customs/clearance systems where needed.

- Local/regional adaptation and governance — systems must be configured to local workflows, regulatory norms, labour practices, and operational realities (e.g., power availability, staff training, maintenance routines).

- Leadership backing & long-term vision — AI‑powered terminals are not “one‑time projects.” They need commitment to continuous monitoring, periodic reviews, and process discipline.

For ports in Indonesia, Vietnam, Kenya, and similar markets where infrastructure growth is rapid but challenging, this may require phased rollout, stakeholder change‑management, and capacity building. But with scale and volume, the ROI can be substantial.

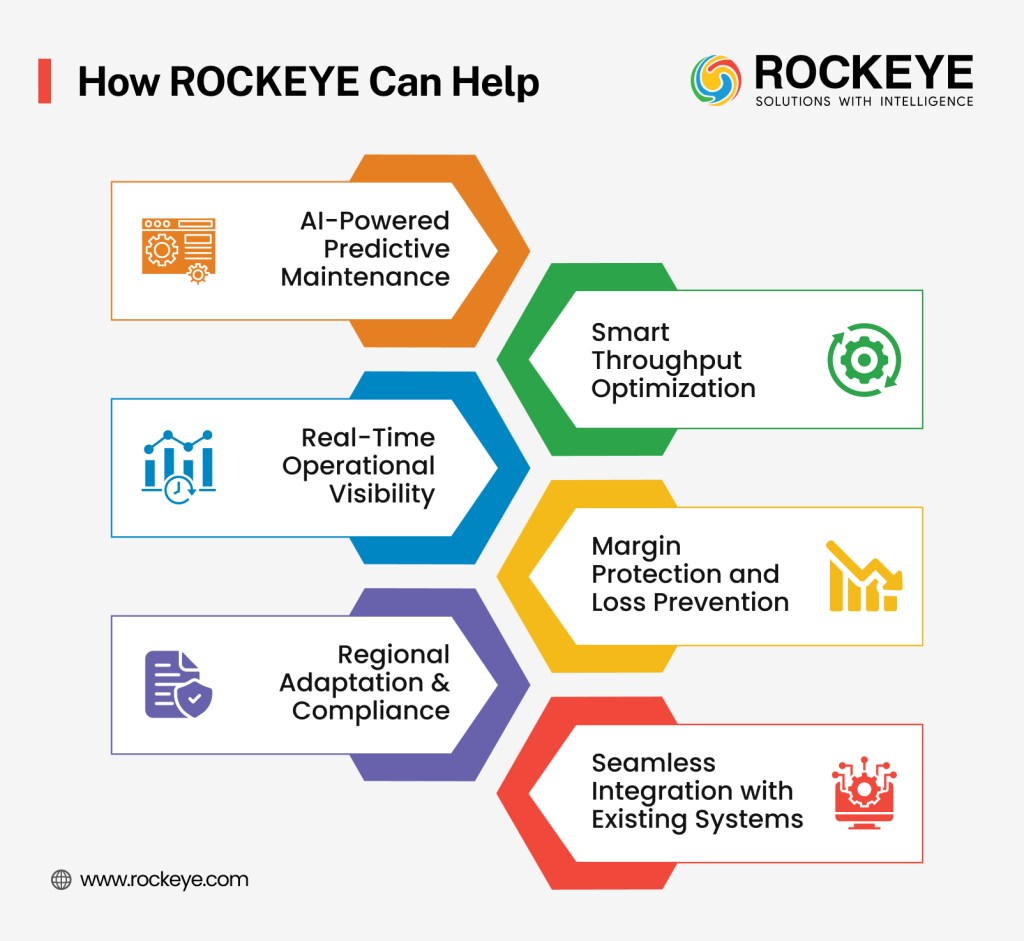

How ROCKEYE Can Help

For ports, terminals, and logistics operators in Malaysia, Indonesia, Vietnam, and Kenya, implementing AI-powered terminal management system solutions is easier and more impactful with ROCKEYE. Unlike generic ERP or legacy software, ROCKEYE is designed specifically as a Downstream Commercial Control System and Terminal Management Platform, focused on reducing downtime, tightening margins, and optimizing throughput.

Here’s how ROCKEYE adds value:

AI-Powered Predictive Maintenance

ROCKEYE monitors cranes, yard vehicles, conveyors, and other critical equipment in real-time. Its AI engine predicts potential failures before they occur, enabling proactive maintenance and reducing unplanned downtime by up to 50%.

Smart Throughput Optimization

The system dynamically manages vessel berths, crane assignments, yard movements, and gate traffic, ensuring smooth container flow and maximum utilization of assets. This directly increases throughput while minimizing congestion.

Real-Time Operational Visibility

ROCKEYE consolidates data from sensors, gates, yard systems, and vessels into a central dashboard, giving decision-makers full visibility into equipment health, container flow, and operational bottlenecks all in real time.

Margin Protection and Loss Prevention

By combining terminal operations management with advanced analytics, ROCKEYE helps prevent leakage, reduces idle time, and ensures transactions and cargo handling remain fully compliant, protecting margins and boosting profitability.

Regional Adaptation and Compliance

ROCKEYE is built to adapt to local operational and regulatory conditions across Southeast Asia and Africa. Whether in Mombasa, Jakarta, Hai Phong, or Port Klang, it supports local workflows, labour practices, and reporting requirements.

Seamless Integration with Existing Systems

ROCKEYE easily integrates with existing container terminal operating systems, TMS terminals, and port management software, ensuring a smooth digital transformation without operational disruption.

In short: ROCKEYE transforms your terminal from a reactive operation into a data-driven, AI-optimized powerhouse, delivering higher throughput, lower downtime, and stronger margins all while making terminal management simpler, smarter, and future-ready.

Why Regional Ports Should Treat AI‑Powered Terminal Management as a Strategic Investment

For ports and terminals across Indonesia, Vietnam, Kenya (and broadly Southeast Asia / Africa), trade volumes are rising fast, supply chains are under pressure, and global trade disruptions are frequent. Traditional, reactive, manual terminal operations simply cannot keep pace.

Implementing a dedicated AI‑powered terminal management system (TMS), ideally as part of a broader Downstream Commercial Control System (DCCS) or integrated terminal management platform, becomes a strategic differentiator. It’s not just about handling more containers or cargo; it’s about building resilience, safeguarding margins, improving asset life, and enabling scalability without proportional cost growth.

For C‑suite leaders (CEO, CFO, CTO, Operations Heads), this translates into: more predictable operations, fewer surprises, better utilization of capital, improved service levels, and ultimately, stronger competitive positioning in a rapidly evolving global trade environment.

Must Read: AI Stock-powered Predictions: How ERP Data Will Forecast Market Volatility in 2026

FAQs

How does AI reduce downtime in terminal operations by 30–50% for ports in Kenya or Vietnam?

By enabling predictive maintenance on cranes/yard equipment and combining that with real-time scheduling of berths, yard moves, gates, and truck flows. This prevents unplanned breakdowns and avoids idle time, two main causes of downtime.

What AI tools improve real-time visibility in port and terminal workflows?

IoT sensors, machine‑learning analytics engines, real‑time dashboards, and, for advanced setups, digital‑twin simulations that mirror terminal operations. Together, they give decision‑makers live insight into operations.

How can predictive maintenance be applied to cranes and yard equipment in growing ports?

Sensors on cranes, conveyors, or vehicles collect data (usage cycles, vibration, temperature). AI models trained on historic failure data detect anomalies and schedule maintenance proactively before failures happen.

Which AI models best optimize terminal throughput and traffic flow in Southeast Asia / Africa ports?

Machine learning for anomaly detection; optimization algorithms for resource allocation (berths, cranes, yard blocks, gates); simulation models (digital‑twin or queuing‑theory based) for throughput capacity, helping plan for vessel arrivals, container stacking, yard allocation, and dispatches.

How does sensor data help AI predict equipment failures in terminals operating in ports like Mombasa or Hai Phong?

Sensors continuously monitor equipment parameters (vibration, temperature, load cycles). AI analyzes this for patterns indicative of wear or stress, triggering maintenance alerts before breakdowns, enabling timely intervention.