If you run a food processing plant in Malaysia, you already know this truth: Your inbound logistics can make or break your profitability.

According to sources like HashMicro’s 2025 logistics report, these delays can cause 15-20% spoilage in perishables, wiping out profits in Malaysia’s humid climate. For Johor packaged food plants, one inbound hiccup often costs thousands in idle lines and wasted stock.

Whether you process poultry in Selangor, seafood in Penang, or packaged foods in Johor, the entire production flow depends on one thing:

Raw materials arriving on time, in the right condition, with zero surprises. But here’s the reality many plant managers quietly admit:

- Why do we still get inconsistent supply from vendors?

- Why does raw material quality vary even after strict SOPs?

- Why do transport delays keep messing up our production plan?

- Why do audits become stressful because files and documents are all over the place?

If these sound familiar, you’re not alone. Most Malaysian food processors struggle with the same issues due to fragmented systems, manual coordination, and legacy tools that simply cannot support modern inbound logistics. This is where Inbound Logistics Optimization in Malaysia becomes more than a buzzword; it becomes a survival strategy. And today, with changing regulations, rising customer expectations, and increasing competition, the shift is clear:

Food plants don’t need another ERP system. They need a complete commercial control system, a full business operating system.

That’s where ROCKEYE enters the story.

Why Inbound Logistics Defines Profitability in Malaysian Food Processing Plants

Every kilogram of raw material that enters your plant influences:

- Production speed

- Quality output

- Food safety compliance

- Cost per unit

- Customer satisfaction

- Your actual margin

But here’s the challenge:

Malaysia’s food market operates within tight freshness windows. Raw materials, such as poultry, seafood, dairy, fruits, and spices, cannot sit idle, be delayed, or arrive in improper condition.

And yet, many plants still face:

- Supplier delays

- Unreliable cold chain logistics in Malaysia

- Incomplete delivery documentation

- Manual GRN errors

- Missed quality checks

- Sudden stock-outs

- Last-minute firefighting

When inbound logistics breaks down, the entire food supply chain’s efficiency takes a hit.

Your production halts, your orders are delayed, and your margins shrink.

Must Read: Downstream Supply Chain Control – Real-time Visibility in Fuel Transport

Understanding Inbound Logistics in the Malaysian Food Processing Ecosystem

Inbound logistics in food processing is more than simply “receiving goods.”

It’s an entire ecosystem that includes:

- Raw material procurement

- Vendor coordination

- Transport planning

- Temperature-controlled logistics

- Quality inspection

- Warehouse receiving

- Documentation & compliance

This ecosystem becomes even more complex in Malaysia due to:

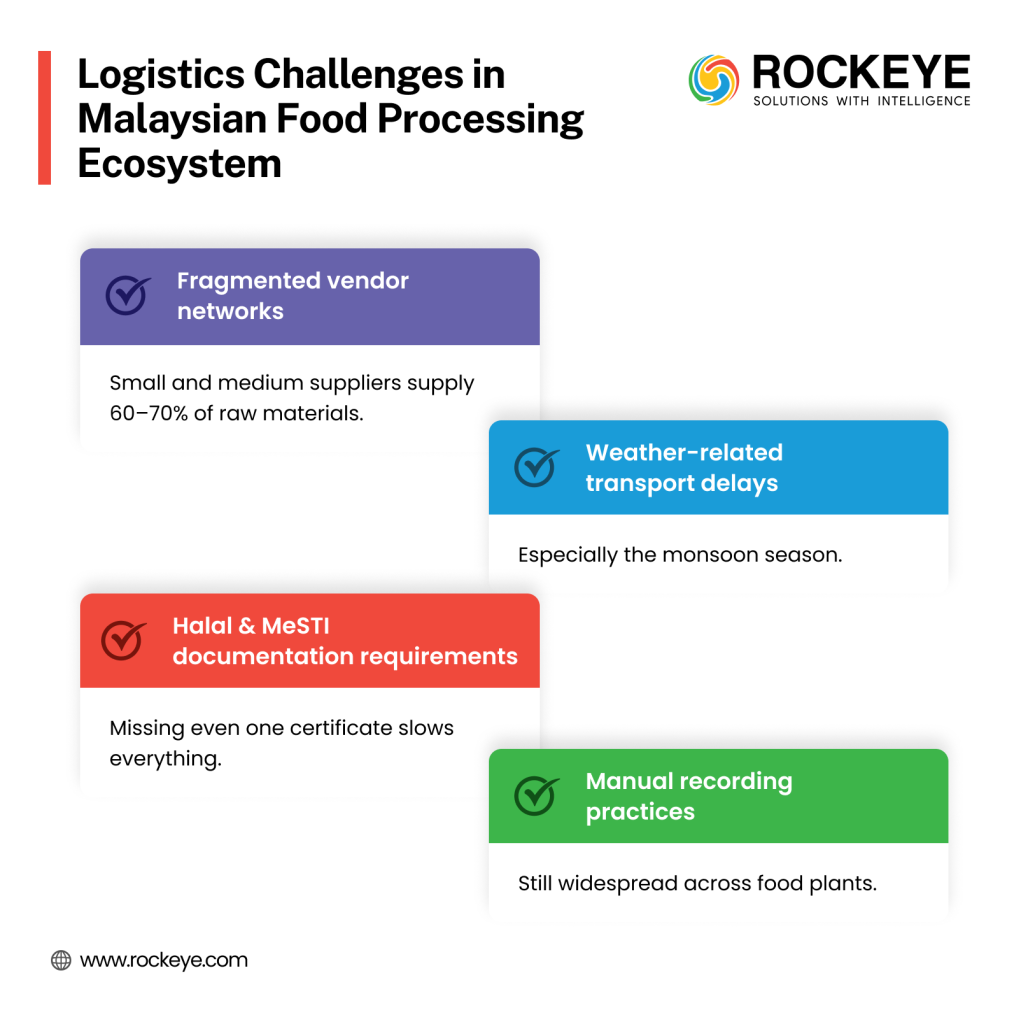

1. Fragmented vendor networks

Small and medium suppliers supply 60–70% of raw materials.

2. Weather-related transport delays

Especially the monsoon season.

3. Halal and MeSTI documentation requirements

Missing even one certificate slows everything.

4. Manual recording practices

Still widespread across food plants.

All these factors make inbound logistics in food processing one of the toughest functions to manage unless everything is connected.

ROCKEYE: The Operating System for Inbound Logistics Optimization

ROCKEYE is built not as another ERP module, but as a Complete Commercial Control System, one that connects procurement, transport, warehouse, production, finance, and compliance into a single, operationally intelligent ecosystem.

For inbound logistics, ROCKEYE delivers:

- Real-time supplier → transport → warehouse → production coordination

- Fully digital cold-chain monitoring

- Smart procurement and vendor performance management

- Automated receiving, inspection, and GRN

- Integrated document & compliance workflows

- AI-driven material readiness and demand planning

- Accurate landed cost breakdown

- Full traceability from supplier to production

It becomes the nerve centre of inbound operations.

Module-by-Module Breakdown: How ROCKEYE Solves Real Inbound Challenges

Below is a deep, operational explanation of how each module contributes to Inbound Logistics Optimization for Food Processing Malaysia.

1. Procurement: The Foundation of Predictable Inbound Supply

Most Malaysian plants still rely on phone calls, WhatsApp, and email to manage suppliers. ROCKEYE eliminates this chaos through its procurement software.

Key Capabilities

1. Demand-driven Purchase Planning

The system calculates exact raw material requirements based on production schedules, reducing unnecessary safety stocks.

2. Smart Supplier Scorecards

- Automated tracking off

- On-time delivery rate

- Temperature compliance

- Quality acceptance rate

- Documentation accuracy

- Pricing consistency

3. Digital Contracts & SLAs

Auto-expiry alerts ensure compliance with HALAL, MeSTI, and food safety certifications.

4. Automated PO → Supplier → Transport Integration

The moment a PO is approved, supplier pickup requests and transport jobs are auto-created.

Operational Impact

- Predictable supply

- Higher vendor accountability

- Lower price variation

- Zero missed contract renewals.

- Faster approvals, less manual follow-up

2. Transport Management & Vehicle Tracking: Real-Time Material Movement Control

Transport delays are one of the biggest pain points for Malaysian plants. ROCKEYE solves this through its transport management system and vehicle tracking system.

Key Capabilities

1. GPS Live Tracking

Allows plants to monitor every inbound truck, ETA, speed, route, and stops.

2. Cold Chain Monitoring

Temperature sensors send real-time alerts if the cold chain is compromised, preventing the loss of perishables.

3. Dynamic Route Optimization

Helps avoid traffic, closures, and predictable delays.

4. Driver Performance Logs

For better route planning and safety compliance.

5. Remote Assist for Disruptions

Plant teams can troubleshoot transport issues remotely.

Operational Impact

- Fewer transport delays

- Higher cold-chain reliability

- Lower spoilage and rejections

- Just-in-Time (JIT) delivery in food processing becomes feasible.

3. Warehouse & Inventory: High-Precision Intake of Raw Materials

Receiving areas in Malaysian plants often suffer from congestion, manual logs, and inconsistent inspection processes. ROCKEYE transforms this by digitizing the entire inbound receiving workflow through its warehouse & inventory module.

Key Capabilities

1. Digital Gate Entry

QR-based or RFID-based vehicle entry cuts wait time.

2. Automated Inspection Workflows

Temperature, appearance, weight, moisture — fully logged.

3. Instant GRN Creation

No manual paperwork.

4. Batch / Lot Tracking

Full traceability across shelf life, supplier, and production line.

5. Material Readiness Engine

The system shows what material is ready, pending, rejected, or under re-inspection.

Operational Impact

- Faster warehouse throughput

- Lower human error

- Accurate real-time stock visibility

- Better coordination with production

4. Document Management & Compliance Control

Malaysian food plants handle a large number of documents:

- HALAL certificates

- MeSTI & GMP approvals

- Delivery orders

- Supplier licenses

- Transport hygiene documents

Missing even one document can delay production or fail an audit. ROCKEYE solves this with its AI-powered document management system that:

- Digitizing all inbound documents

- Auto-matching DO, PO, invoice, certificate

- Generating audit-ready trails

- Creating compliance workflows for every supplier

Operational Impact

- Zero missing documents

- Faster approvals

- Smooth internal & external audits

- Lower compliance risk

5. Production & Maintenance: Ensuring Material Is Always Production-Ready

One of the biggest challenges in Malaysian plants is determining whether the inbound raw materials are fully ready for processing. ROCKEYE solves this by connecting inbound operations directly with production management.

Key Capabilities

1. Production Schedule Integration

Material readiness is automatically checked against upcoming production batches.

2. Quality-based Gatekeeping

If a batch fails inspection, production is notified instantly.

3. Predictive Maintenance

Ensures critical receiving equipment (weighbridges, chillers, conveyors) do not fail during peak inbound hours.

Operational Impact

- Zero production delays due to unknown shortages

- Lower downtime

- Higher material consistency

6. Financial Accounting: Accurate Landed Cost & Supplier Reconciliation

Inbound logistics affects cost more than any other area. ROCKEYE helps plants understand the real cost per batch through financial accounting software. Key features include:

- Automated invoice matching

- Landed cost calculation (transport, handling, quality loss)

- Supplier penalty enforcement (late delivery, failed inspection)

- Real-time cost variance analysis

This gives COOs and CFOs transparent insights that drive better procurement planning and supplier negotiations.

Might Enjoy Reading: From Manual Processes to Smart Accounting: A Complete Transition Guide

What an Optimized Inbound Logistics Workflow Looks Like with ROCKEYE

Here is the typical end-to-end flow inside a modern Malaysian food processing plant:

- Production demand triggers procurement planning.

- ROCKEYE generates smart POs

- Supplier accepts → transport scheduling happens automatically.

- Live tracking + temperature monitoring begins.

- The warehouse prepares for arrival.

- GRN auto-created → stock updated instantly

- Production line receives readiness notification.

- Finance reconciles invoices automatically.

- Traceability reports are generated for compliance.

This level of synchronization is impossible with traditional systems.

Frequently Asked Questions

1. What is inbound logistics in food processing plants?

Inbound logistics in food processing refers to the entire process of moving raw materials from suppliers to the production facility. It includes supplier coordination, transport scheduling, cold chain management, quality checks, warehouse receiving, and documentation. In Malaysian plants, effective raw material handling in food plants is critical to ensure materials arrive on time, in the right condition, and ready for production. Proper inbound logistics management directly impacts food supply chain efficiency, minimizing delays and spoilage while maintaining compliance with standards like HALAL, MeSTI, and GMP.

2. Why is inbound logistics optimization important for Malaysian food processing companies?

nbound Logistics Optimization in Malaysia is vital because it ensures the timely and accurate delivery of raw materials, which directly affects production schedules, product quality, and operational costs. Malaysian food processors face unique challenges such as fragmented supplier networks, unpredictable transport conditions, and cold chain logistics in Malaysia. Optimizing inbound logistics helps companies improve Malaysian food industry logistics optimization, reduce wastage, enhance Just-in-Time (JIT) delivery in food processing, and maintain compliance with regulatory and safety standards. Without optimization, plants risk delays, higher costs, and inefficiencies in the overall food supply chain.

3. How can food processing plants improve raw material receiving efficiency?

Improving raw material receiving efficiency involves a combination of technology, process design, and workflow integration. Best practices include:

- Digitalizing warehouse intake: Use systems like food traceability software Malaysia to track batches, temperatures, and supplier details in real-time.

- Automated inspection and GRN generation: Reduces manual errors and speeds up the intake process.

- Integration with procurement and production planning: Ensures the right materials arrive Just-in-Time (JIT) delivery in food processing without overstocking.

- Cold chain monitoring: Real-time alerts ensure perishable materials meet quality standards.

Staff training and standardized SOPs for raw material handling in food plants.

By implementing these strategies, Malaysian food processors can significantly reduce bottlenecks and enhance Inbound Logistics Optimization for Food Processing Malaysia.

4. What are the biggest inbound logistics challenges faced by Malaysian food processors?

Some of the top challenges include:

- Fragmented supplier networks: Multiple small vendors increase coordination complexity.

- Transport and traffic unpredictability: Delays affect production schedules.

- Cold chain logistics Malaysia compliance: Maintaining proper temperature for perishable goods is critical.

- Manual processes and paperwork: Lead to errors, slower receiving, and missing documents.

Traceability gaps: Difficulty in tracking raw materials from supplier to the production line affects audits and quality control.

Addressing these challenges requires Inbound Logistics Optimization in Malaysia solutions that integrate procurement, transport, warehouse, and compliance functions in a single platform.

5. How can food processing plants reduce inbound logistics costs and improve efficiency?

Food processing plants can reduce costs and improve efficiency by:

- Optimizing procurement: Using data to select the best vendors and negotiate better rates for raw material procurement food industry.

- Streamlining transport: Route planning, live vehicle tracking, and predictive scheduling reduce fuel, delays, and downtime.

- Enhancing warehouse operations: Automating receiving, inspection, and batch tracking improves throughput.

- Implementing cold chain monitoring: Prevents spoilage and reduces product losses.

Integrating systems for end-to-end visibility: Real-time dashboards for cost, stock, and supplier performance enable informed decision-making.

These strategies ensure Malaysian food processors achieve Inbound Logistics Optimization for Food Processing Malaysia, maximize food supply chain efficiency, and maintain high product quality.

6. What technologies can improve inbound logistics performance in the food processing industry?

Several technologies can transform inbound logistics performance:

- ERP and business operating systems: Platforms like ROCKEYE provide complete Commercial Control System capabilities, connecting procurement, transport, warehouse, and production.

- Food traceability software Malaysia: Ensures batch-level visibility from supplier to production line.

- IoT-enabled cold chain monitoring: Real-time temperature tracking prevents spoilage of perishable goods.

- GPS vehicle tracking and route optimization: Improves transport efficiency and enables Just-in-Time (JIT) delivery in food processing.

- AI-powered predictive analytics: Forecasts supplier performance, inbound delays, and raw material shortages.

Digital document management: Automates compliance checks, certificates, and audit trails.

By leveraging these technologies, Malaysian food processing companies can achieve Malaysian food industry logistics optimization, minimize costs, and ensure seamless inbound logistics in food processing operations.