Industrial plants across ASEAN, the GCC, and Africa lose 4–12% of their margins every year because inbound, production, outbound, commercial, and financial processes run in separate systems. ERPs record movements, but they cannot validate, enforce, or prevent leakage at the point of action.

In today’s volatile manufacturing landscape:

- 64% of manufacturers report declining OTD.

- ASEAN PMI fluctuations show unstable production cycles

- Cyber tampering on industrial assets has doubled since 2024.

- Labor shortages bring operations down to 70–75% effective capacity.

Plants operating only on ERP visibility suffer from leakage, disputes, compliance blind spots, and throughput volatility.

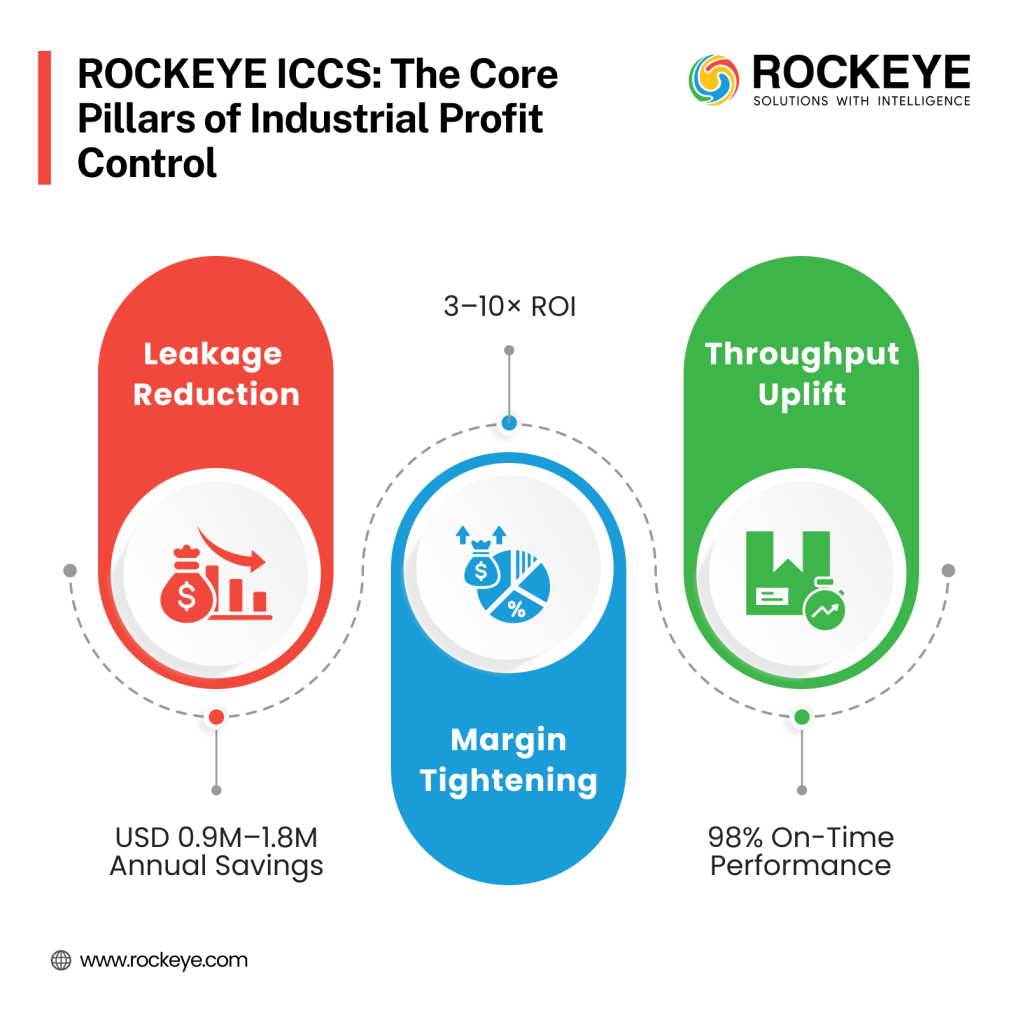

Plants using ICCS, however, consistently achieve 98% on-time movements with annual leakage recovery of USD 0.9M–1.8M, driven by real-time validation of every inbound load, production event, outbound dispatch, and financial transaction. Most plants recover their investment in 3–7 months, with a 3–10× ROI depending on volume, complexity, and contract structures, because ICCS prevents losses before they hit the books.

Because ERP records. ICCS controls. And control is the only way to protect the margin. If you want to know more, let’s dive in.

Why Industrial Plants Lose Margin (and Why ERP Cannot Stop It)

Margin erosion comes from hundreds of micro-leaks that ERPs cannot see or prevent:

Weight manipulation, PO–GRN mismatch, contractor overbilling, route deviation, FEFO errors, idle fleet, diversion, unverified equipment usage, rate-slab misuse, FX variance leakage, ghost inventory, and non-compliant dispatches.

Even well-run plants lose 4–12% margin annually.

The Real Problems for Plant Leadership

- Production Head

Inbound unpredictability is the biggest destabilizer of OEE and production flow. A 30–90-minute delay can derail kilns, alter batch sequencing, create ghost inventory, and degrade shift performance.

- Finance Director

Finance struggles because ERP cannot validate rate, weight, route, or contract compliance at the point of action. FX variance and contract leakage surface only during audits, long after recovery windows close. ICCS removes audit dependency and prevents variance before finance books it.

- Inventory Head

Dispatching through WhatsApp or Excel causes dwell time, demurrage, mis-slotting, and inbound congestion. Without a governed movement layer, there is no reliable source of truth for trucks, batches, or stock movements.

- Procurement Head

Contractors exploit blind spots through overbilling, misuse of rate slabs, and weight variance. PO–DO–GRN–Invoice alignment becomes slow and manual, leading to leakage that goes undetected.

- Maintenance Head

Unexpected downtimes and inconsistent asset utilization occur because inbound delays disrupt maintenance windows. Missing logs, fuel variance, and unverified run-hours create gaps that inflate maintenance costs and reduce availability.

Each of these problems is a commercial control failure, not just a visibility failure.

Also read: Downstream Supply Chain Control-Real-time visibility in Fuel Transport.

Industry-specific Margin Leaks

Cement & Steel

- 2–4% weight variance at the gate = 6-7 figure annual loss

- Shrinkage across clinker, slag, and ore

- Demurrage spikes from manual gate cycles

- 10–15% OTD drops due to inbound volatility

ICCS impact:

Enforces weighbridge integrity, route validation, kiln sync, and demurrage control.

Mining & Foundries

- 5–12% contractor overbilling

- Manipulated tonnage

- Idle machinery + micro-shutdowns from unpredictable inbound

- 3–5 day dwell without synchronized scheduling

ICCS impact:

ICCS governs trip authentication, load integrity, and inbound production sync.

FMCG, Agro & Cold Chain

- 1.8–3.5% FEFO errors

- 8–11% spoilage from temperature excursions

- Mis-sequencing breaks batch integrity

- Asset downtime impacts freshness & throughput

ICCS impact:

It enforces FEFO, live temp monitoring, route control, and traceability.

Industrial Machinery & Equipment Rental

- Fuel misuse accounts for 6–9% cost leakage

- Missing run-hour logs trigger dispute cycles

- Operator misuse accelerates breakdowns

- SCADA tampering exposed in 25.6% of GCC plants

ICCS impact:

ICCS applies encrypted telemetry, run-hour verification, and safe maintenance governance.

Also read: How AI-powered TMS Transforms Oil & Gas Logistics

Why ERP Visibility Fails Industrial Plants

ERP relies on manual entry and after-the-event reconciliation. By the time data appears, the loss has already occurred. ERP does not enforce rules in real time and cannot ingest sensor truth or detect tampering/diversions.

Most critically, traditional ERPs lack commercial governance. ERP asks: “What happened?” ICCS asks: “What should happen? Did it happen? If not, stop the loss immediately.”

Introducing ROCKEYE ICCS: Your Plant’s Commercial Command Layer

ROCKEYE ICCS is engineered as a financially governed, tamper-proof, real-time commercial control system for industrial plants. It does not replace ERP, MES, or TMS. It governs them. ICCS becomes the command layer that validates, enforces, and controls every inbound, production, outbound, commercial, and financial event.

ROCKEYE ICCS Architecture

ROCKEYE ICCS runs on five tightly integrated layers. Each layer maps directly to one or more of the three governance pillars that define our GTM: Financial Governance, Operational Throughput Control, and Predictive Intelligence.

1. Data Capture Layer

Weighbridge, GPS, RFID, temperature sensors, SCADA, fuel meters, and asset logs feed real-time field truth into ICCS. This layer enables predictive scheduling, anomaly detection, and governed workflows.

2. Validation Layer

PO, DO, GRN, weighbridge, invoice, rate, route, batch, and sequence are auto-validated at the point of action. This prevents leakage, manipulation, and disputes before they reach Finance.

3. Business Rules Layer

Contract terms, rate slabs, minimum weight, FEFO, approved routes, FX limits, demurrage triggers, and tolerance thresholds are enforced in real time. This guarantees accurate commercials and stabilized plant operations.

4. Commercial Governance Layer

Real-time approvals, tamper detection, diversion alerts, and dispute prevention ensure every transaction is compliant and traceable. The system stops non-compliant actions before they create loss.

5. Audit & Finance Layer

A 360° audit trail with immutable logs ensures financial integrity. Month-end reconciliation becomes cleaner and more predictable because ICCS prevents variances before Finance books them.

Zero manual manipulation. Zero leakage. Fully governed operations.

ROCKEYE ICCS: The 3 Commercial Proof Pillars

1. Leakage Reduction (Direct Profit Recovery)

Stops shrinkage, overbilling, route deviation, and weight manipulation.

Savings: USD 0.9M–1.8M annually per plant

2. Margin Tightening (Commercial Accuracy)

FX protection, contract enforcement, rate-slab governance.

3–10× ROI based on throughput volume

3. Throughput Uplift (Predictability + Capacity)

Automated slotting, synchronized inbound–production–outbound cycles.

98% on-time performance without increasing fleet or workforce.

Commercial Wins for a Steel Plant Using ROCKEYE ICCS

A leading carbon-steel manufacturer used ROCKEYE ICCS to close its largest leakage points:

Leakage Reduction

The plant eliminated overbilling, stopped raw material shrinkage, and blocked all unauthorized route deviations. Every inbound load was auto-validated, ensuring that no hidden losses slipped through the system. This delivered USD 1.2M in direct profit recovery within 12 months.

Margin Tightening

Rate manipulation was fully removed, and contracts were applied correctly across every transaction. Invoice-to-weighbridge mapping cleaned up reconciliation and eliminated recurring dispute cycles.

Throughput Uplift

Predictive slotting and automated gate cycles stabilized movement across the plant. Production, yard, and dispatch operated in sync, enabling 98% on-time delivery without adding trucks.

ICCS vs Traditional ERP: Why Plants Need Commercial Control (Not More Software)

| Capability | Traditional ERP (rewritten) | What You Actually Need (rewritten) |

|---|---|---|

| Visibility | Captures activities only after they occur, offering limited real-time operational insight. | Live movement visibility via GPS, sensors, weighbridges, and event-level data. |

| Governance | Policies are defined but frequently overridden; approval cycles are slow and manual. | Automated, rule-based enforcement at every operational touchpoint. |

| Audit | Relies on monthly reconciliations and manual cross-checks across multiple reports. | Instant, tamper-proof audit trail for every transaction or movement. |

| Cost Management | Cost leakages surface late; teams use manual corrections to fix inconsistencies. | Real-time cost protection with automated validations from dispatch to payment. |

| Mobility | Mobile tools offer limited viewing capabilities; field actions still rely on paper or calls. | Complete mobile workflows for operators—scanning, approvals, alerts, and updates in real time. |

| Predictive Insights | Historical dashboards only show past trends; forecasting is unavailable. | Predictive alerts that anticipate delays, failures, congestion, and risk. |

| Process Continuity | Modules function in isolation, creating delays and integration gaps. | A unified, connected control layer spanning procurement to finance without delays. |

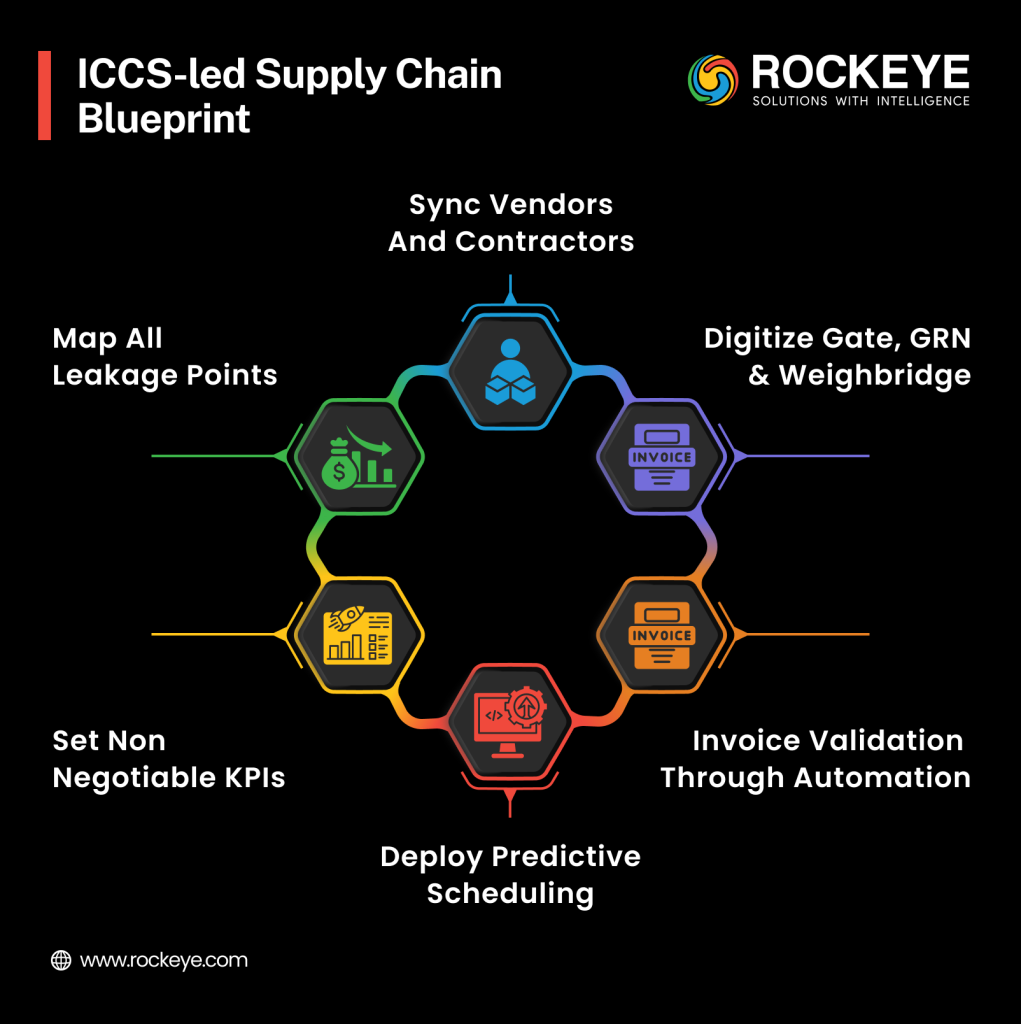

Designing an ICCS-Led Integrated Plant Supply Chain: A Practical Blueprint

Building an ICCS-driven supply chain is not an IT upgrade; it’s a commercial transformation that links every operational event to its financial outcome.

For CFOs, COOs, and Plant Directors, the goal is simple: remove leakage, enforce governance, and accelerate throughput without disrupting existing ERP workflows.

Here’s a practical blueprint aligned with ROCKEYE’s GTM pillars.

1. Map All Leakage Points (Inbound → Production → Outbound)

Identify where margin disappears today: weighbridge mismatch, raw material shrinkage, misallocated inventory, idle fleet, detention/demurrage, under-billed dispatches, contractor overclaims. ICCS tags each point with sensors, digital logs, and commercial rules to ensure every movement is validated before it affects cost.

2. Sync Vendors & Contractors Into a Controlled Ecosystem

Bring suppliers, transporters, and contractors onto ICCS with contract-bound digital workflows. Rate cards, penalties, volume slabs, and service-level rules are auto-enforced—stopping manipulation and ensuring predictable procurement and logistics costs.

3. Digitize Gate, GRN, and Weighbridge Operations

Replace paper registers with real-time gate passes, GRNs, trip logs, and tamper detection. ICCS integrates weighbridge readings, GPS routes, seal checks, and timestamps, ensuring zero manual interference and clean stock intake data for production planning.

4. Automate Movement ↔ Invoice Validation

Every load, ton, and kilometer is automatically matched against the PO, contract, and delivery conditions. ICCS prevents overbilling, detects diversion, and blocks invoice processing until all commercial rules are met, protecting margins before finance gets involved.

5. Deploy Predictive Scheduling for Inbound & Outbound

With slot optimization, ETA prediction, traffic patterns, and real-time queue visibility, ICCS reduces gate congestion and boosts truck turns. Plants gain faster dispatch cycles, fewer bottlenecks, and 98%+ on-time delivery performance.

6. Set Non-negotiable KPIs for Cost & Efficiency

Track KPIs tightly aligned to ICCS capabilities:

- OTD

- Logistics Cost Per Ton

- Shrinkage & Leakages

- Inbound/Outbound Cycle Time

- Working Capital Days

- Dispatch Uptime & Fleet Utilization

These become live dashboards feeding daily operations, not quarterly MIS reports.

Conclusion

Manufacturers no longer lose margin because operations are complex. They lose margin because ERP cannot enforce commercial outcomes.

ROCKEYE ICCS gives CFOs and COOs the real-time command layer to:

- Detect every leak

- Enforce every contract

- Govern every movement

- Protect every dollar

- Stabilize every shift plan

- Achieve predictable throughput

- Unlock 7-figure annual savings

For plants with annual volumes above 100,000 MT, ICCS is not a digital upgrade; it is the operating backbone for margin-first manufacturing.

FAQs

1. How is ICCS different from traditional “end-to-end supply chain visibility” tools?

Most visibility-only platforms only show what is happening. ICCS enforces what should be happening. Typical visibility platforms provide dashboards, location tracking, and delay alerts. These non-governing SCV tools tell you the status of loads or batches, but:

They cannot validate or enforce commercial rules. ICCS is a Commercial Control System, not a visibility layer. It validates every inbound, warehouse, production, outbound, and financial event using rules, contracts, and sensor data, preventing loss.

2. How does ICCS deliver true end-to-end visibility for industrial plants?

ICCS integrates every step of the industrial value chain, from procurement and inbound logistics tothe weighbridge, warehouse, production, outbound movement, commercial workflows, and finance. It captures sensor inputs such as GPS, weighbridge, RFID, temperature, and fuel meters, along with movement events like trip logs, load validation, and batch scans. It also ingests commercial documents such as PO–DO–GRN–Invoice, asset data including run hours and maintenance compliance, and financial controls covering rate, route, and contract rules.

By connecting these layers, ICCS converts simple visibility into verification and real-time enforcement. Every operational and commercial event is validated against rules, preventing leakage, ensuring compliance, and protecting cost, margin, and throughput across the plant.

3. What role does ICCS play in integrated supply chain management (ISCM)?

Integrated supply chain management requires:

- Connected systems

- Connected events

- Connected commercial logic

- Connected decisions

However, most plants run ERP, MES, TMS, weighbridge, and contractor systems separately, creating blind spots.

ICCS becomes the “commercial glue” between them, creating a unified operational and financial truth. It transforms fragmented operations into an integrated, financially governed supply chain that operates as a single system.

4. How does ICCS enable stronger supply chain integration and collaboration with vendors, fleets, and partners?

ICCS integrates suppliers, fleets, and contractors into a single rule-driven ecosystem where every PO, trip, weight, and invoice is auto-validated. Diversion, tampering, and overbilling are eliminated at the source, while real-time digital PODs and timestamps reduce disputes and automatically enforce contract terms.

For production partners, batch flow, sequencing, and consumption become fully transparent, with variances detected instantly. Inbound predictability reduces downtime and changeovers, keeping lines stable. Commercial and finance teams benefit from automated claim validation, stronger invoice integrity, and month-end cycles that shrink from weeks to minutes.

5. How does ICCS improve throughput, reduce dwell time, and stabilize OEE?

Industrial throughput breaks down when inbound becomes unpredictable, warehouse sequences fall out of sync, trucks arrive late, and ghost inventory disrupts planning. Wrong dispatch slotting, manual load planning, and the absence of real-time production-to-yard coordination further compound volatility, causing avoidable delays and unstable shift performance.

ICCS resolves these issues through predictive arrival scheduling and continuous synchronization across inbound, warehouse, production, and yard. Outbound is auto-slotted to eliminate queues, while rule-based loading ensures the right SKU, batch, and weight every time. By removing manual planning errors and operational variability, ICCS restores stable, high-throughput plant performance.

6. Can ICCS integrate with MES or TMS systems already in place?

ICCS does not replace ERP, MES, or TMS; it governs them. It connects via APIs, sensor hubs, and data pipelines, pulling in contracts, POs, invoices, and master data from the ERP; production signals from the MES; and trip metadata from the TMS. Field truth from weighbridges, GPS, RFID, and sensors completes the picture.